(2) Late Model Citizen Miyano ABX-64THY2 Twin-Spindle, Triple-Turret Lathes & Nakamura AS-200L - Offers Encouraged

Starts: 19 June 2025 at 12:00 BST

Ends: 31 July 2025 at 15:00 BST

Available now late model machinery due to new investment moved to our Kettering Storage Facility for convenience. Buyer will need versa lift to load to their transport. NOTE: Vendor to approve all closing bids prior to Apex final invoicing. Please see the sale information section for any additional fees that may be applicable upon purchasing an item.

Share:

Showing 3 of 3 lots

- LOT 1

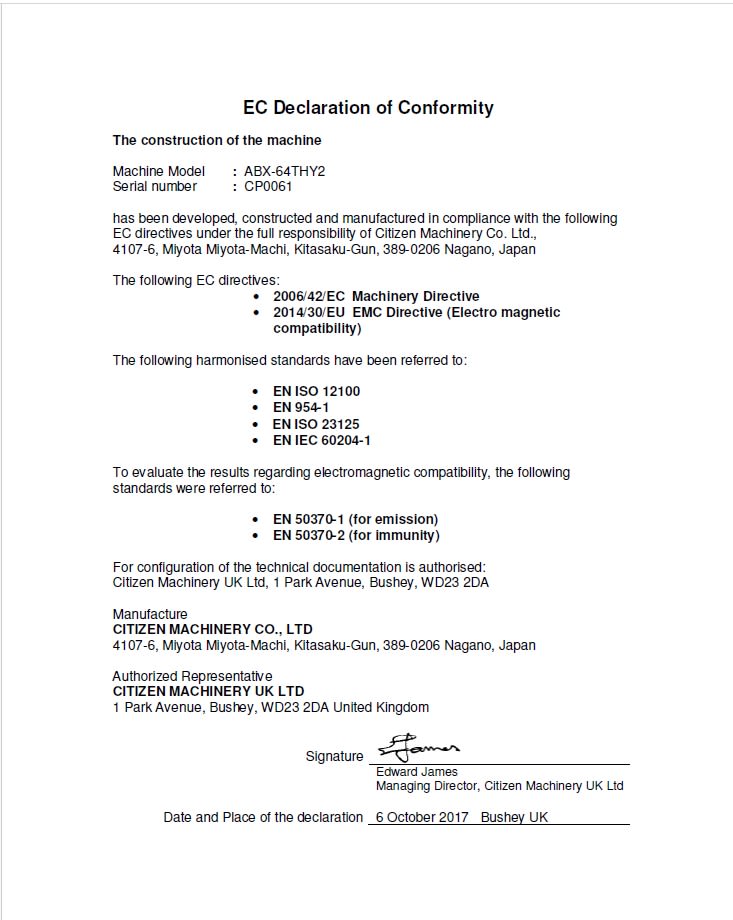

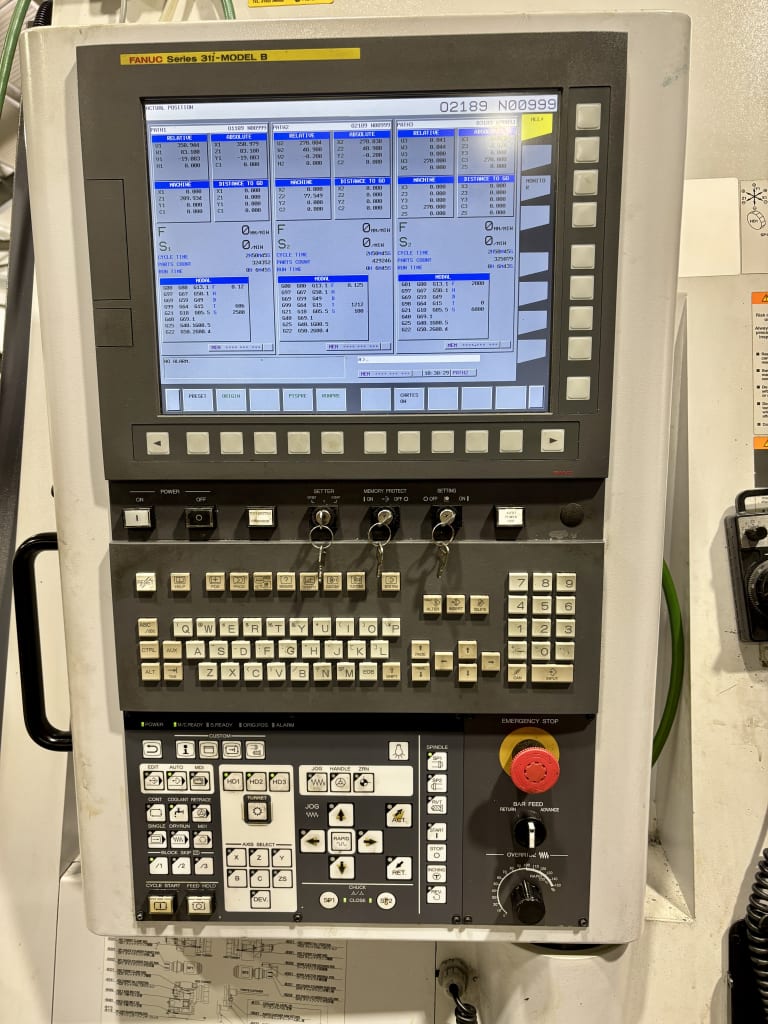

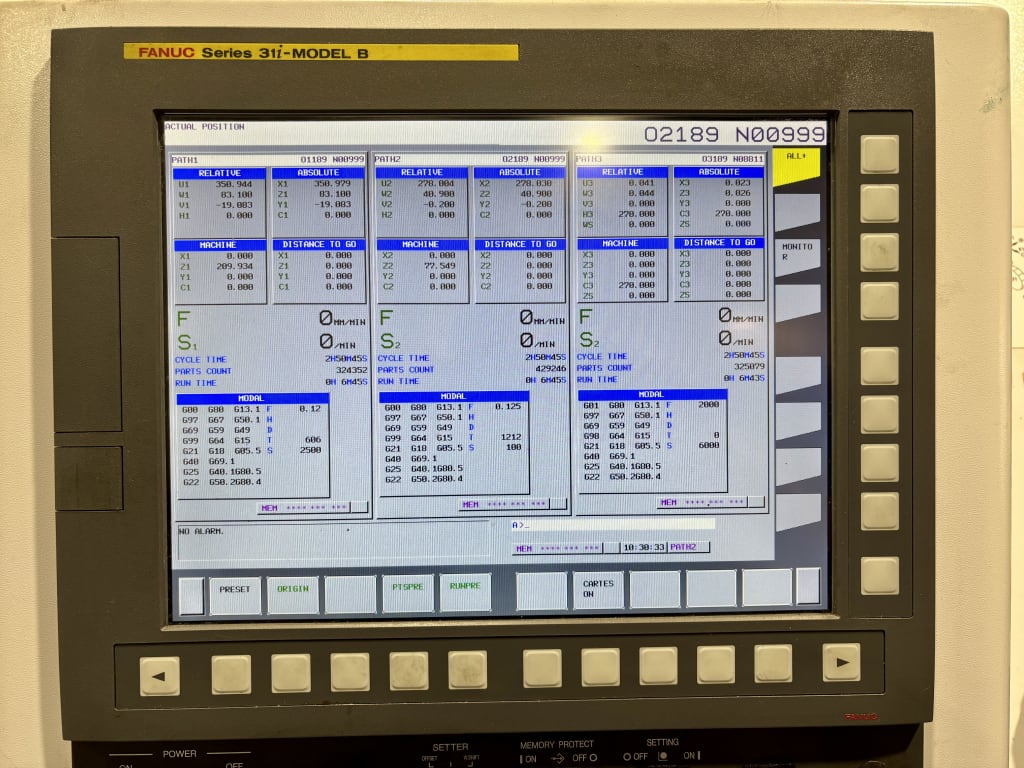

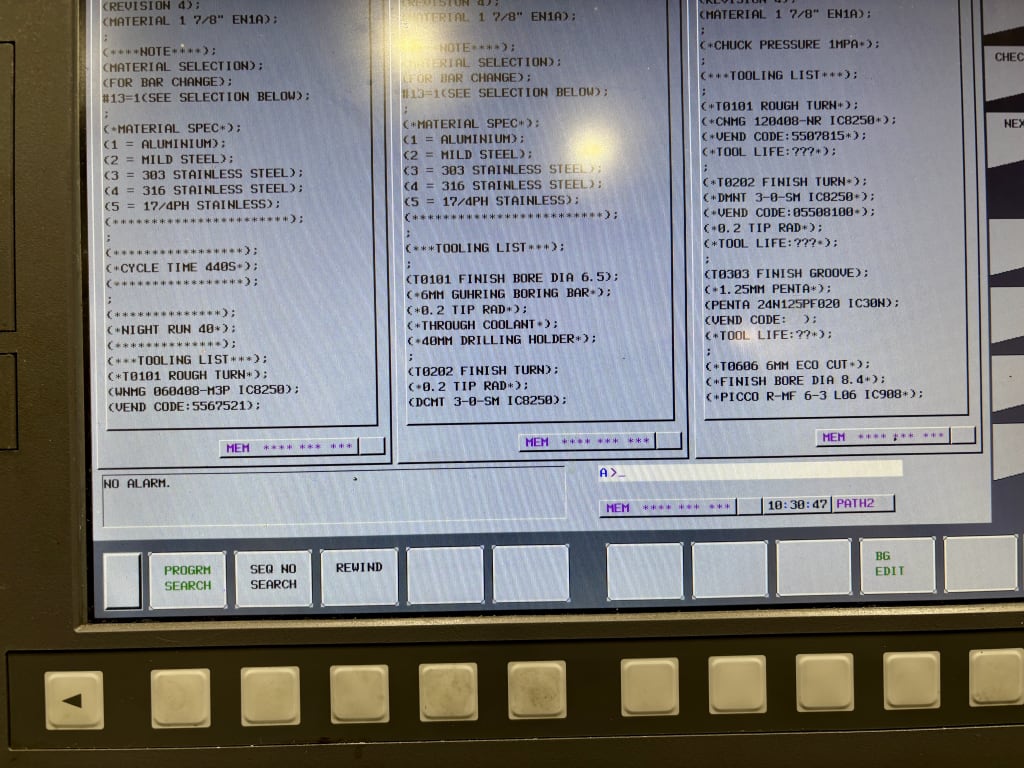

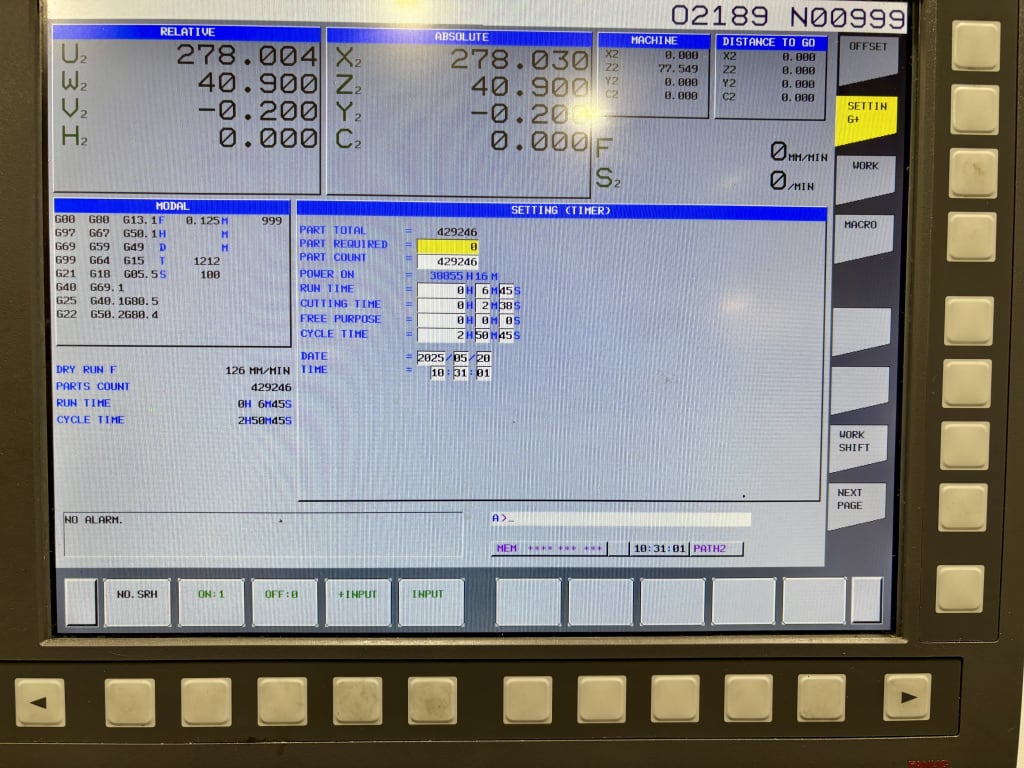

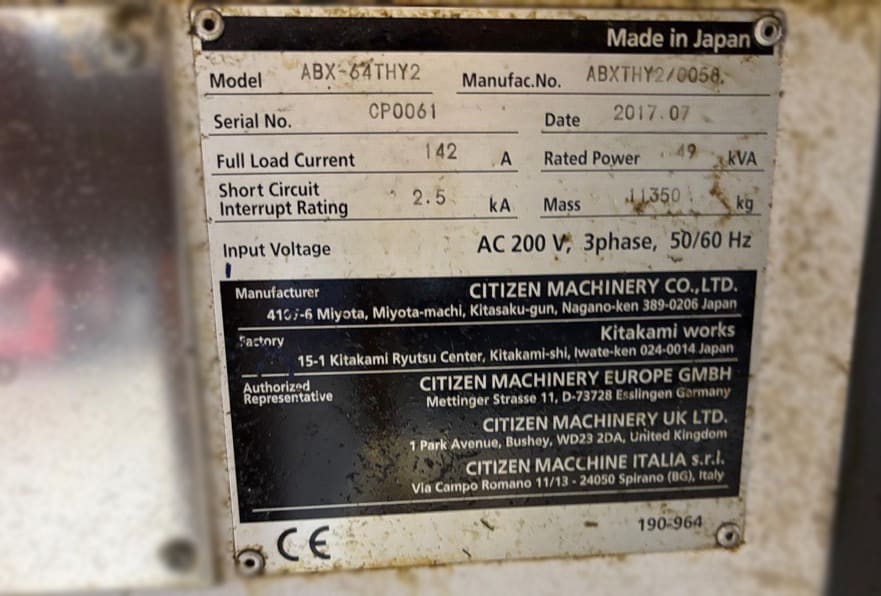

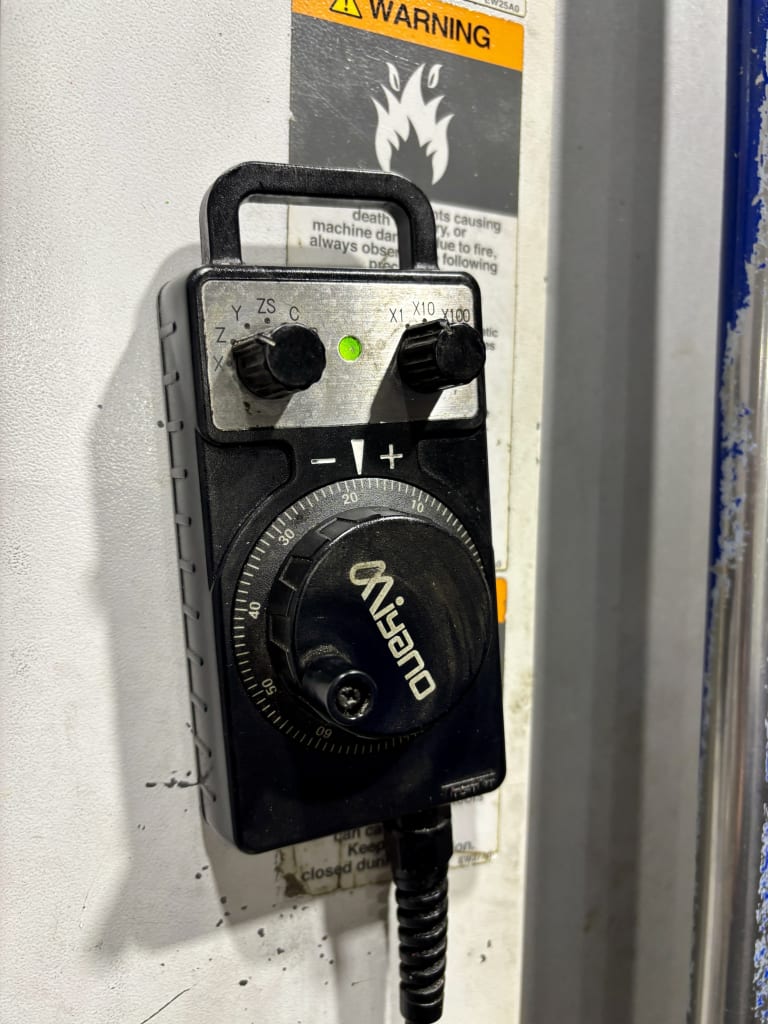

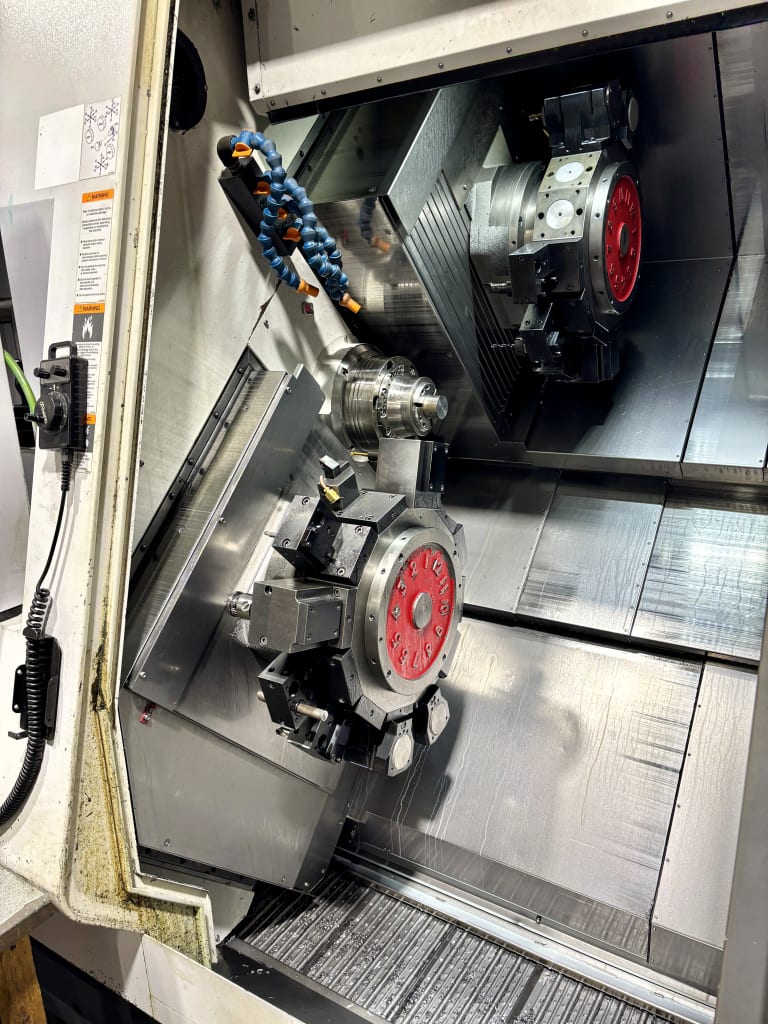

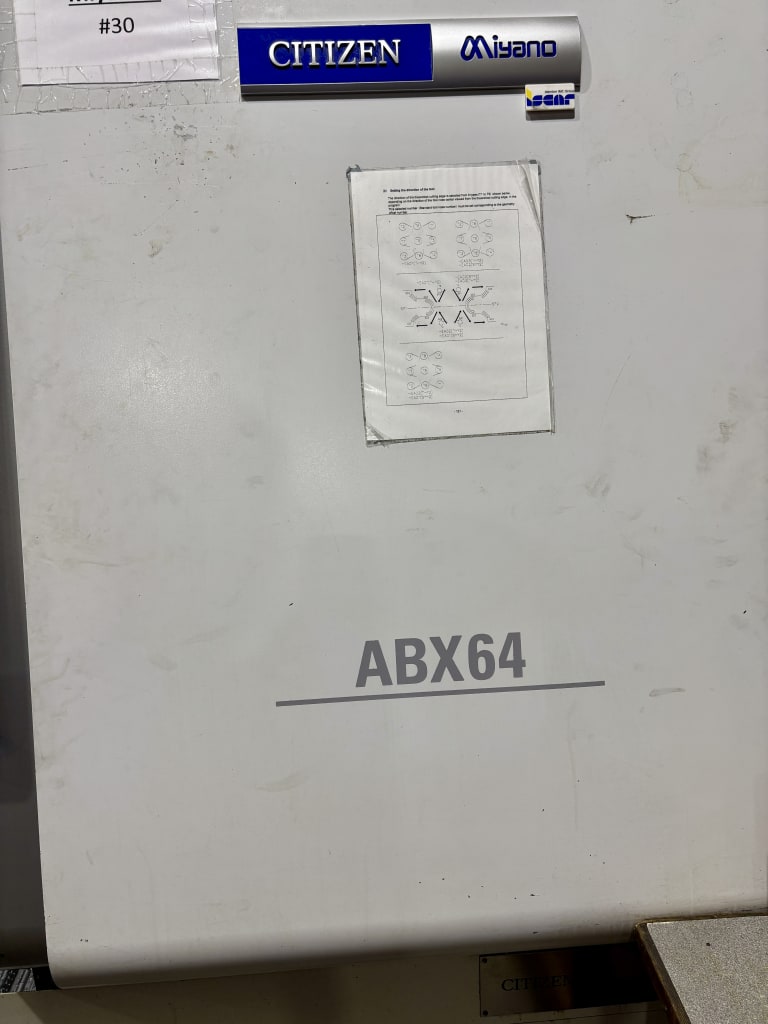

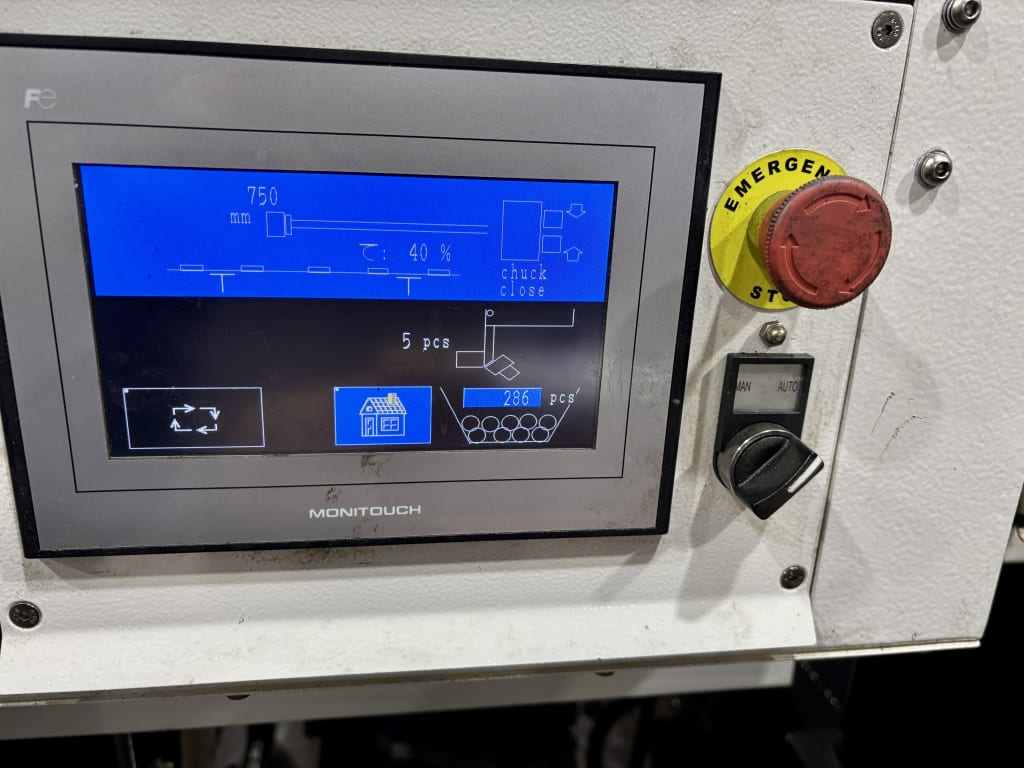

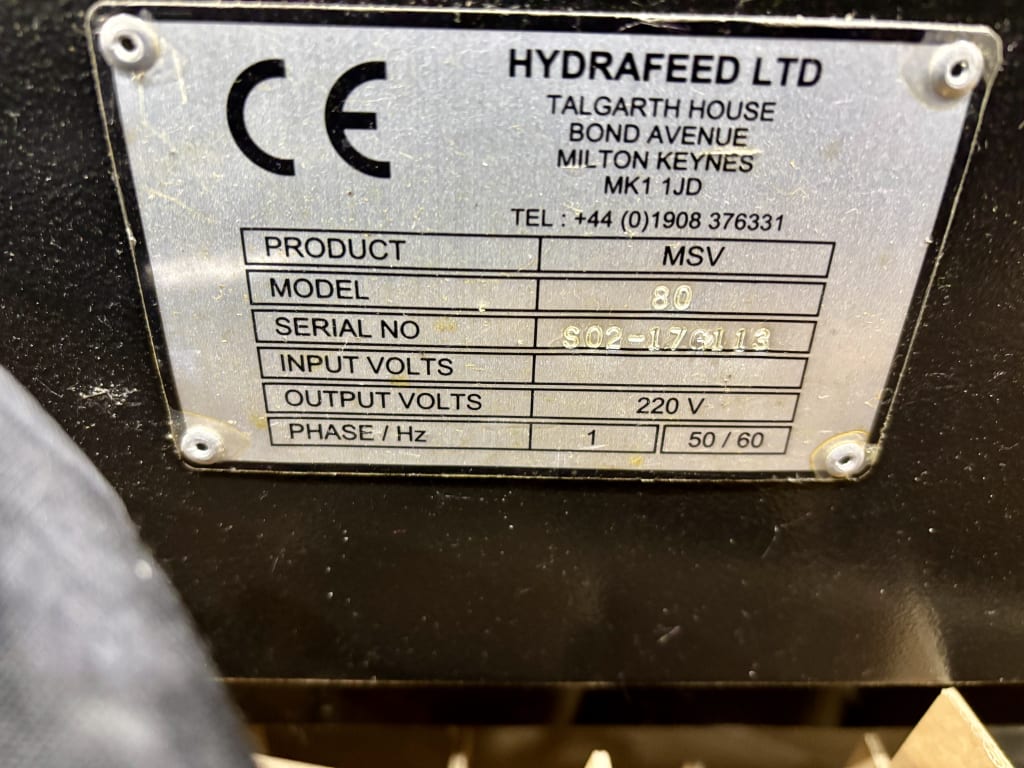

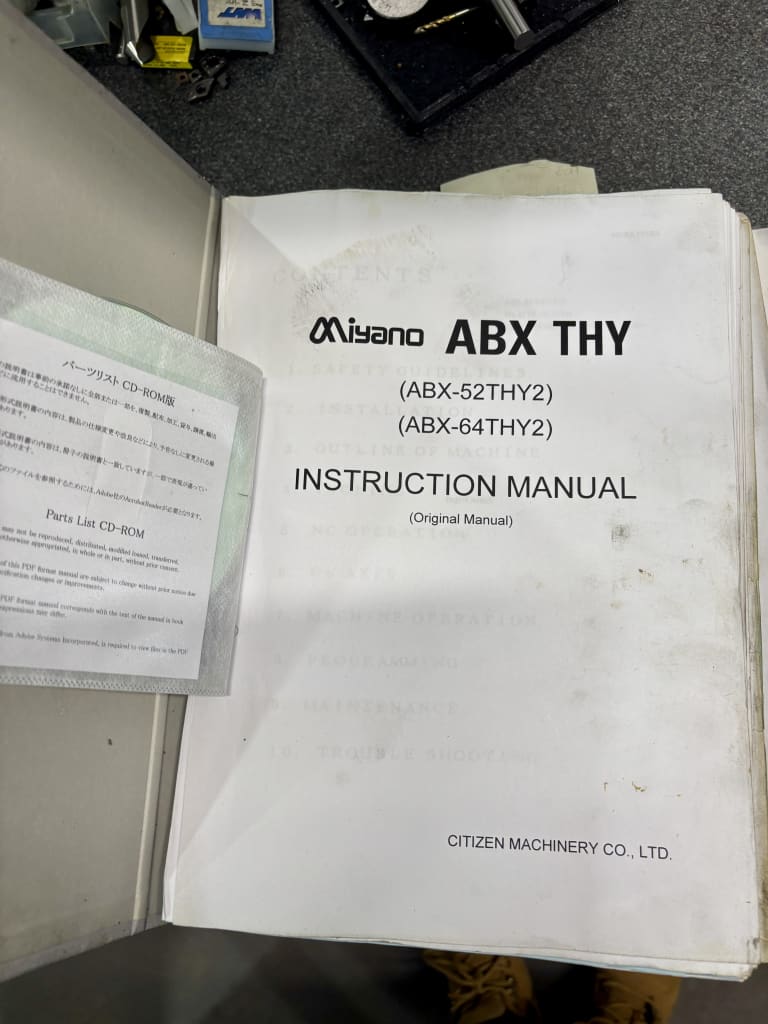

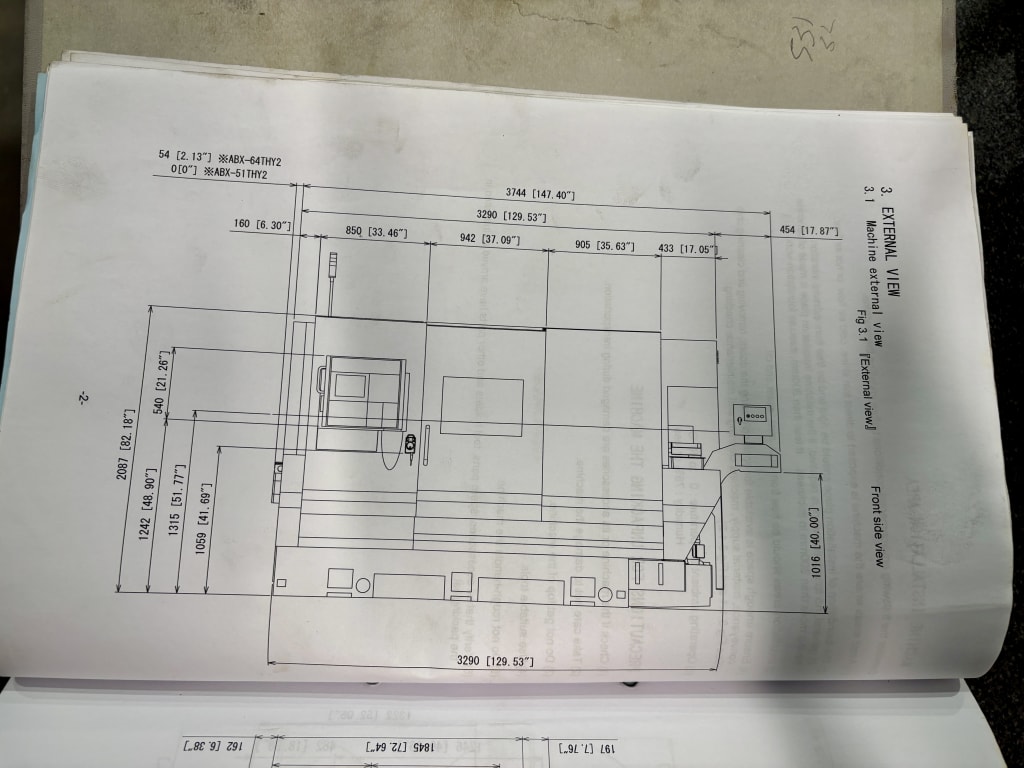

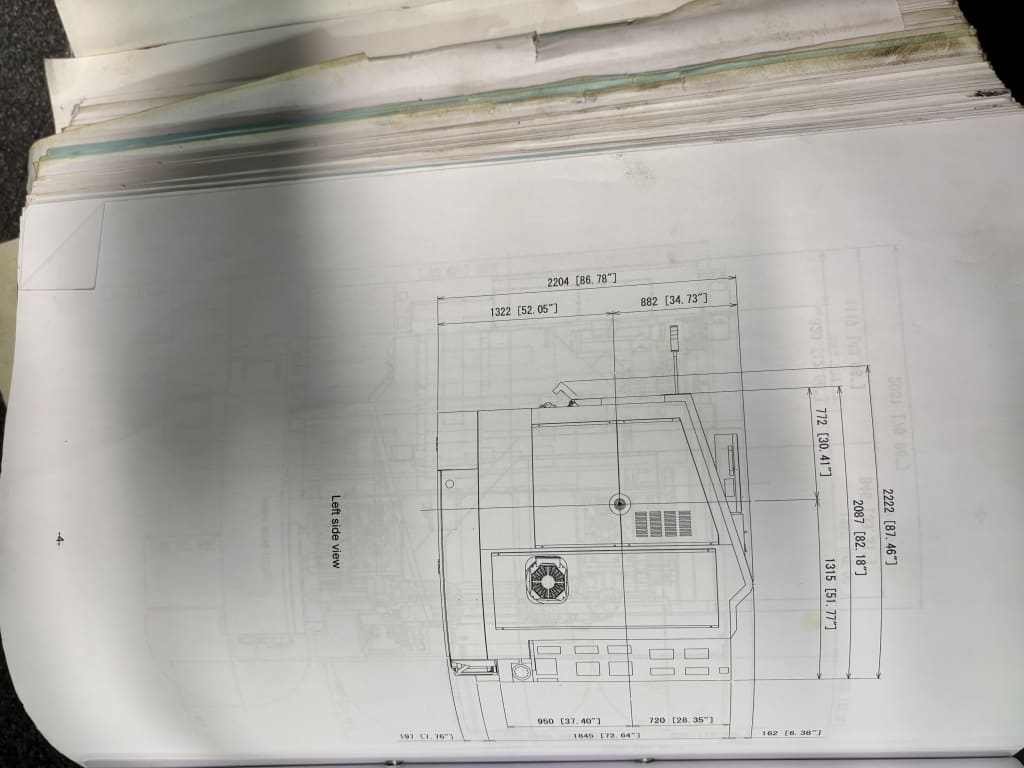

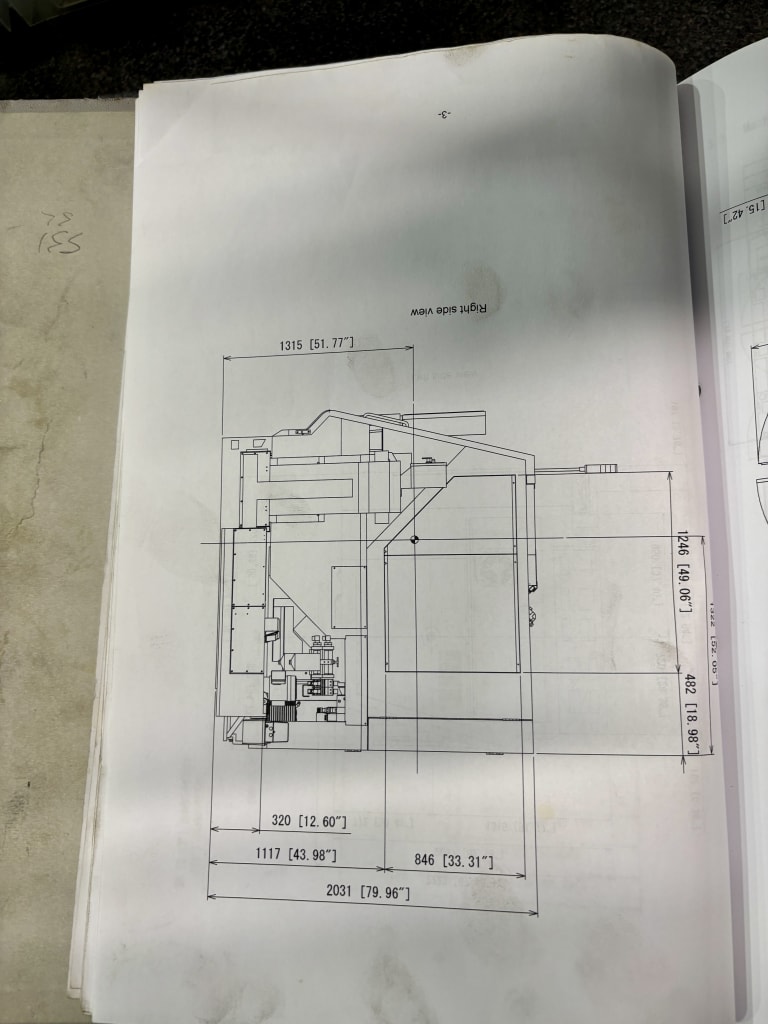

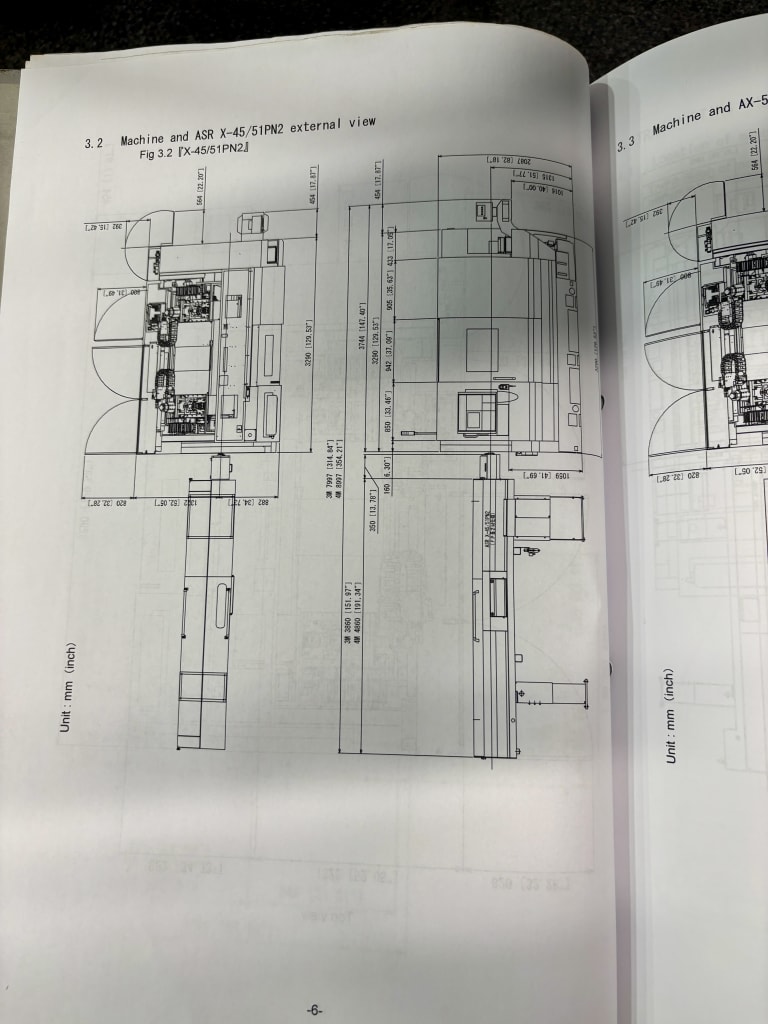

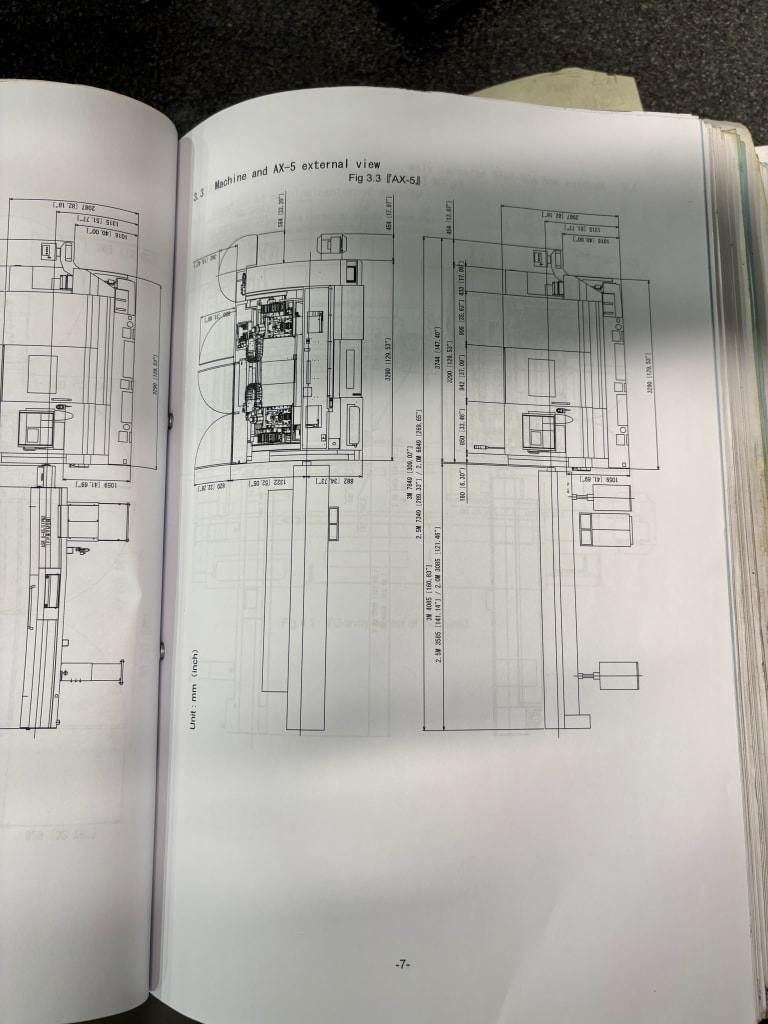

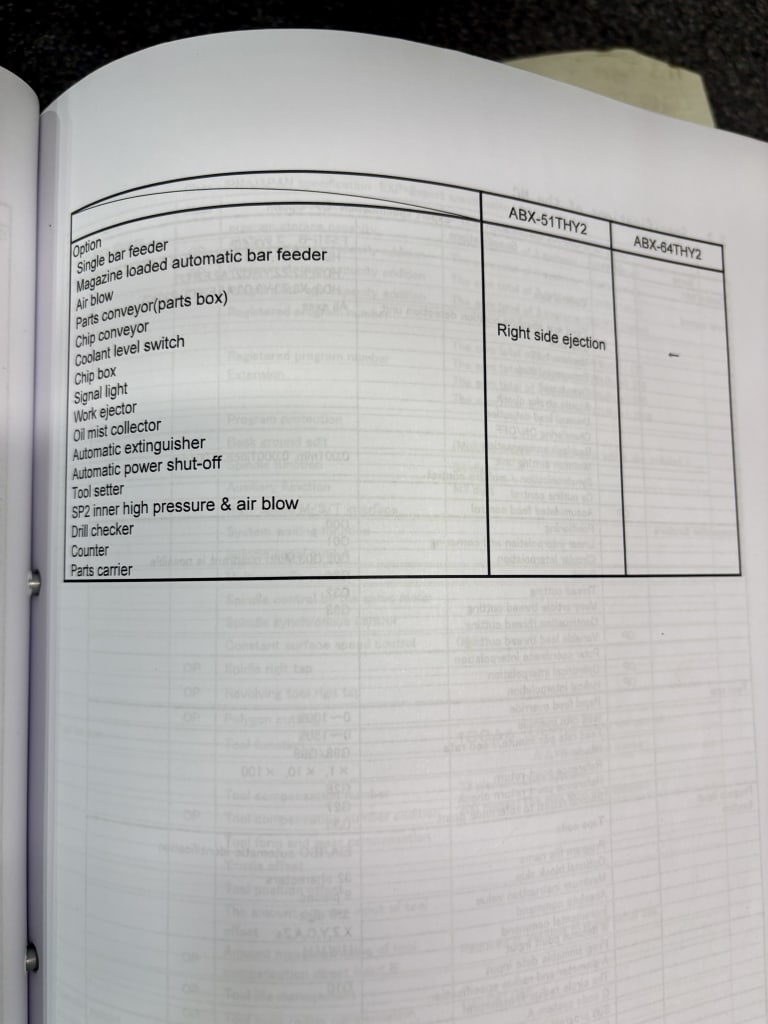

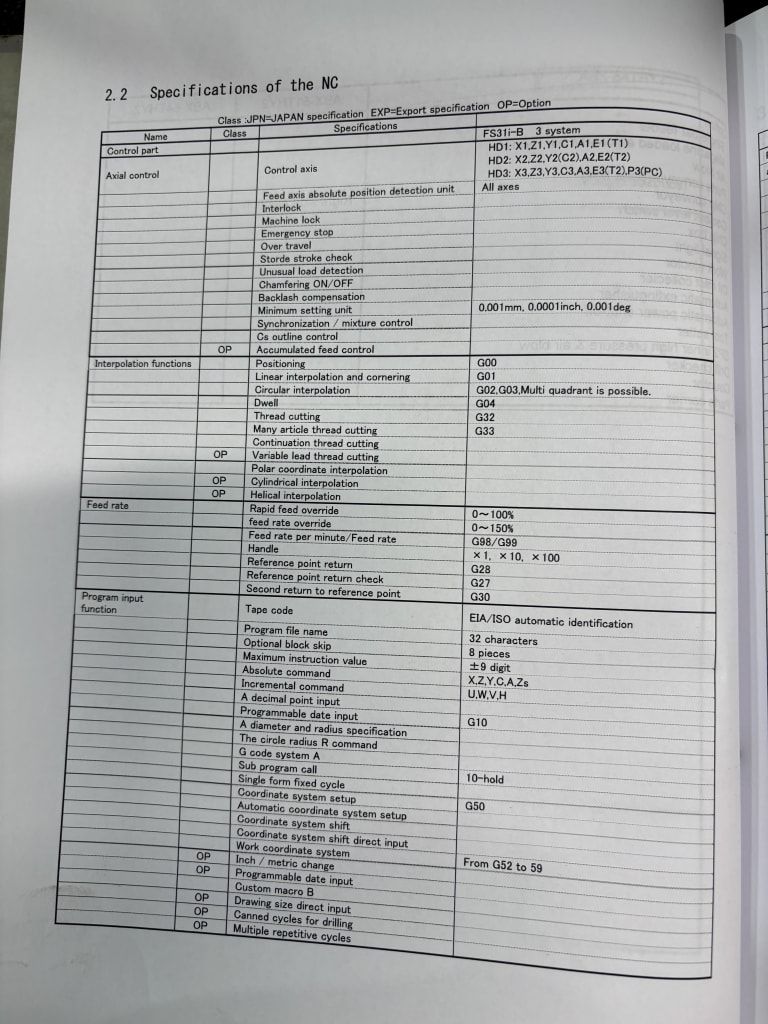

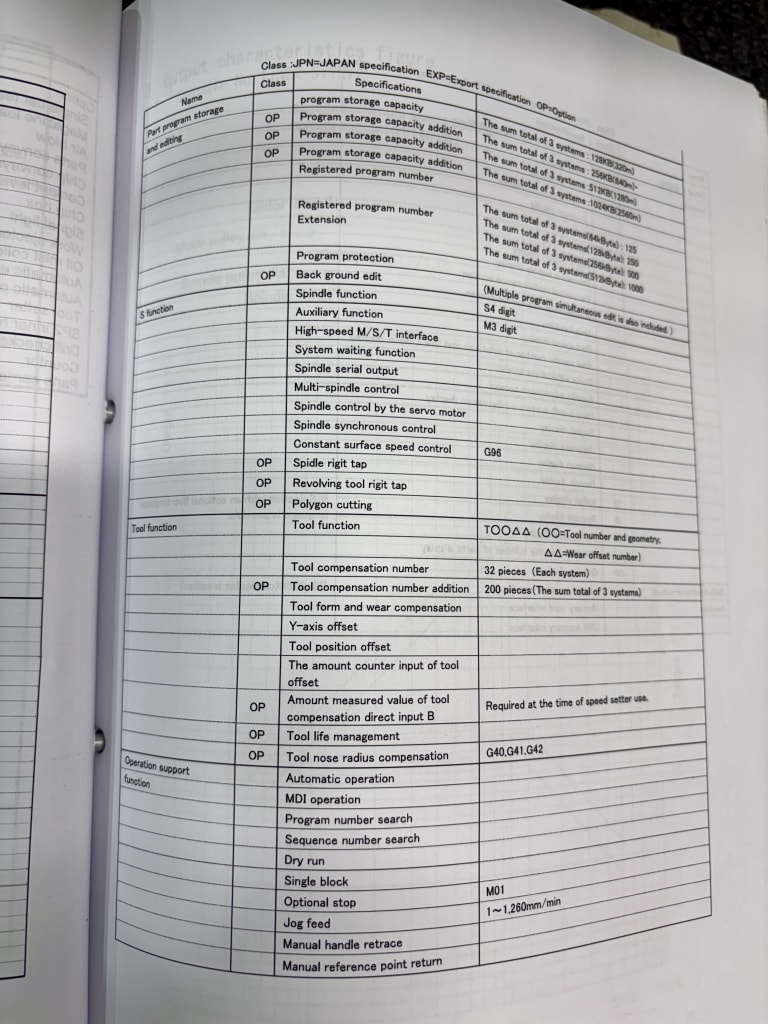

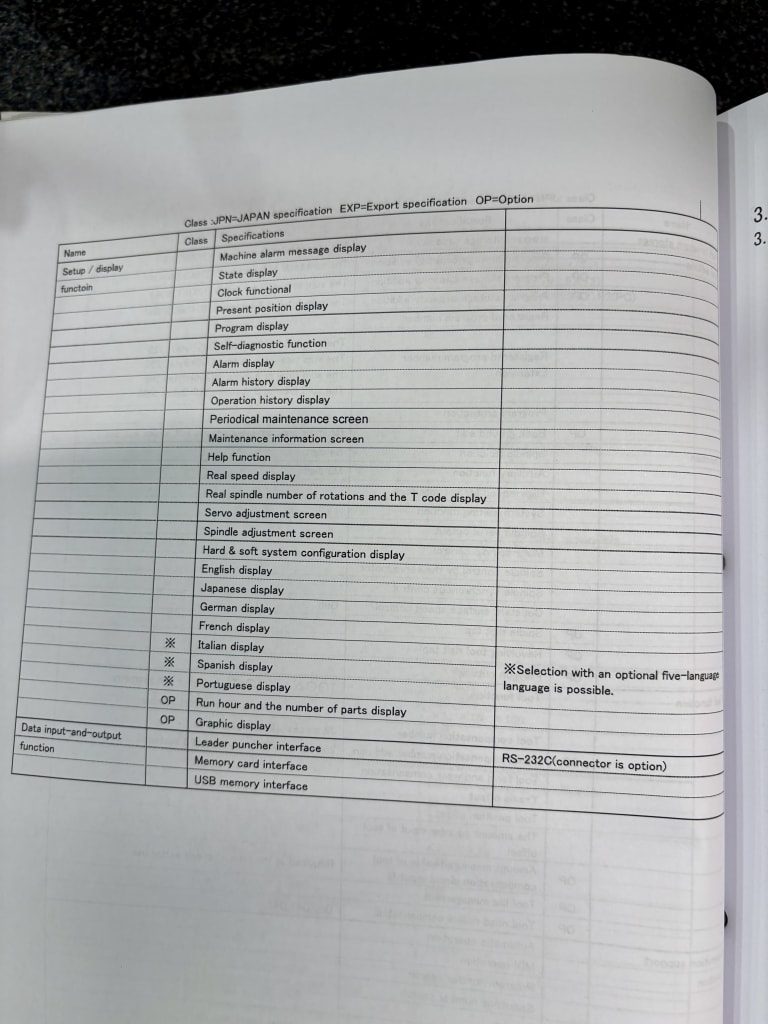

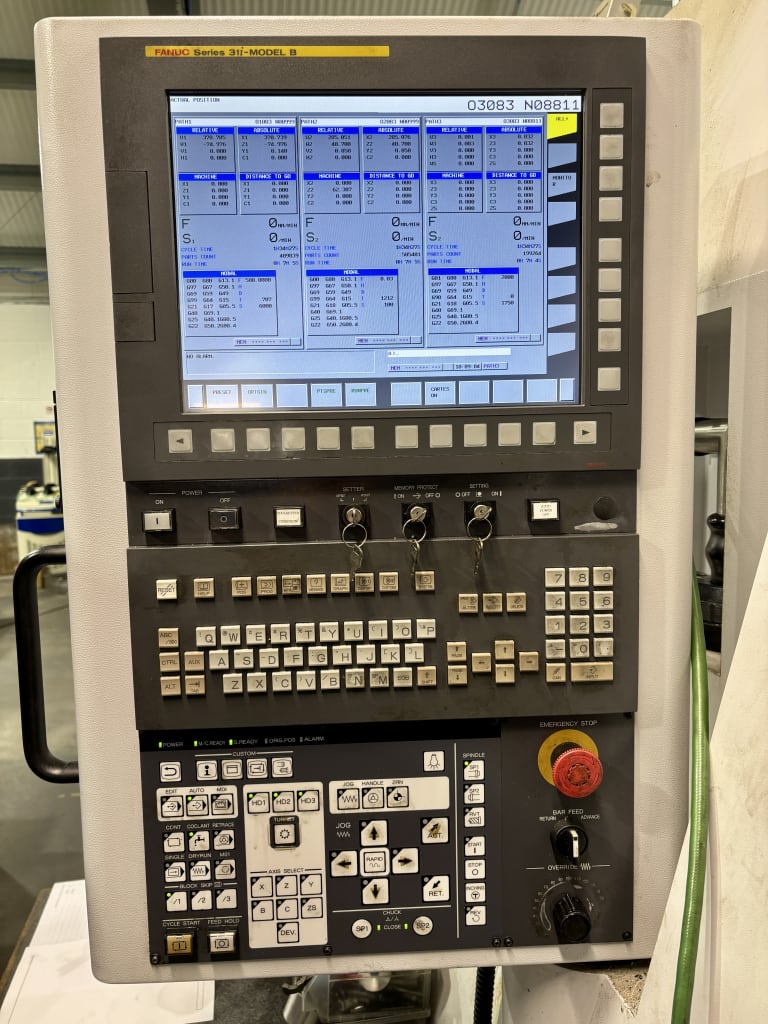

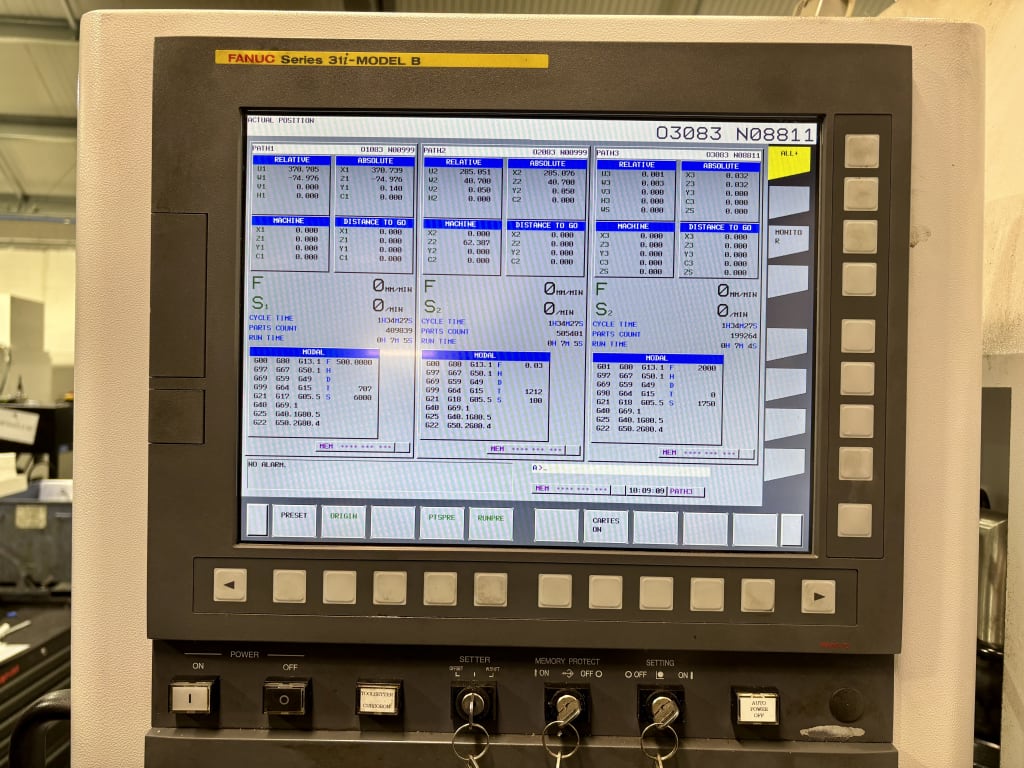

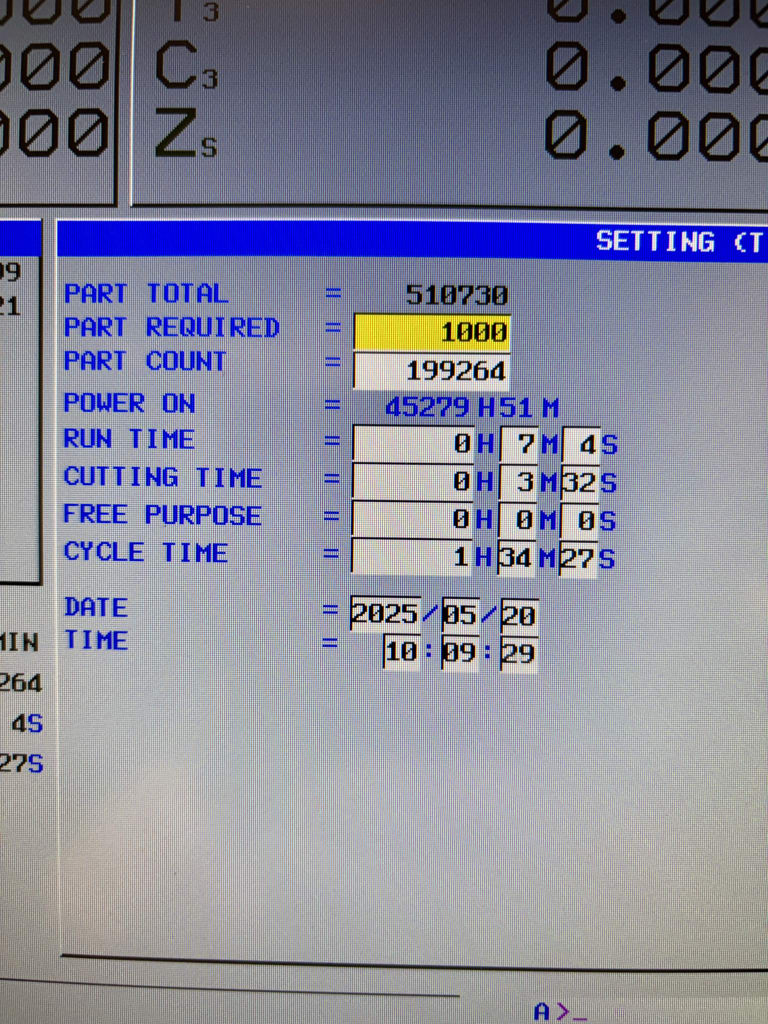

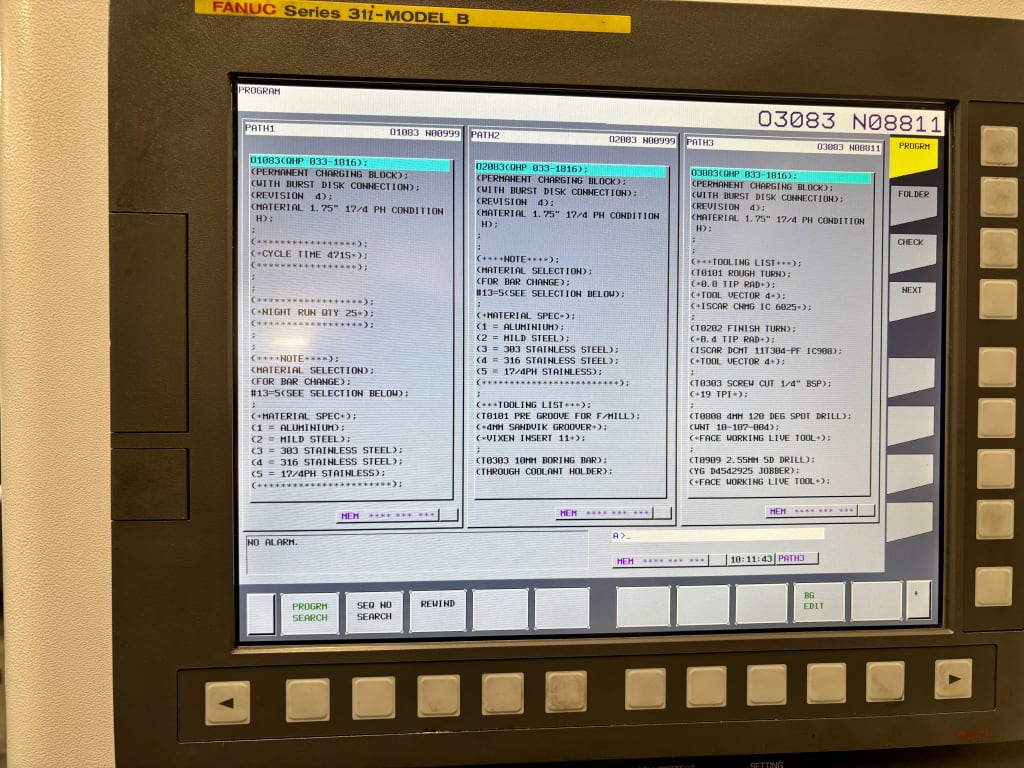

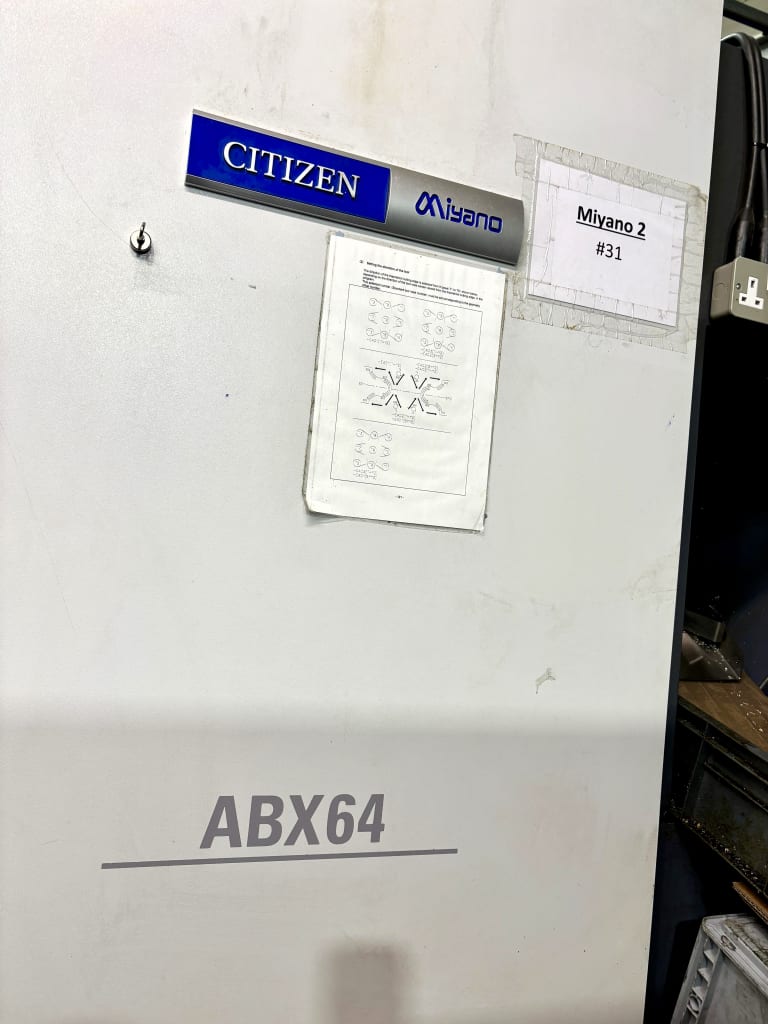

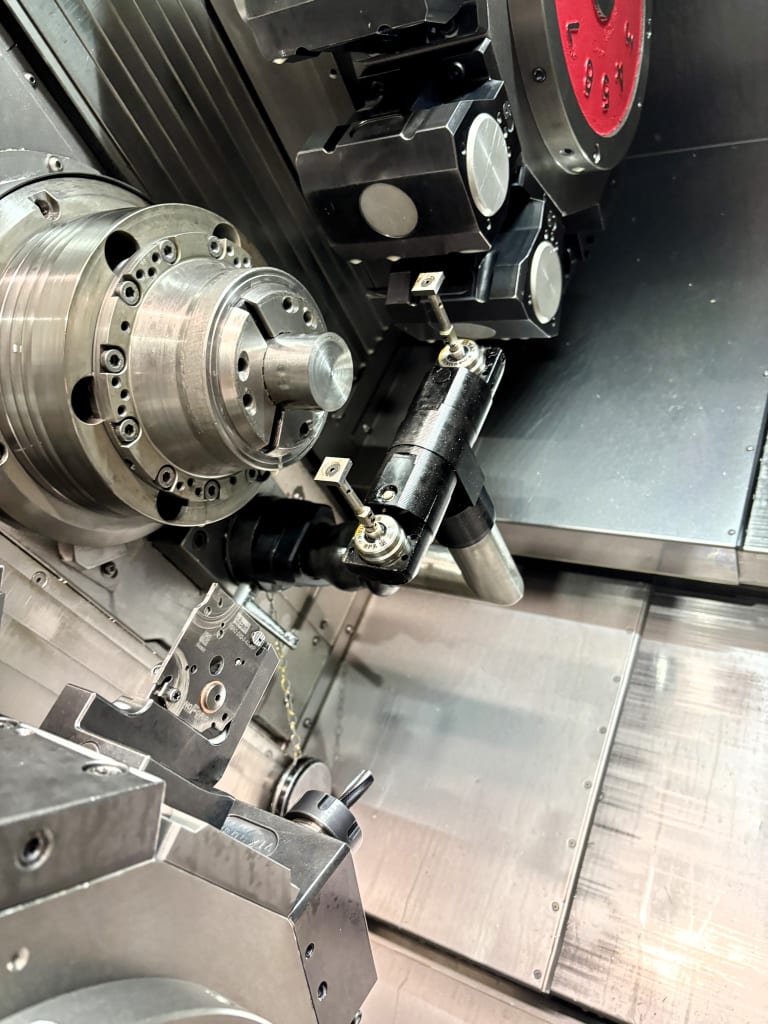

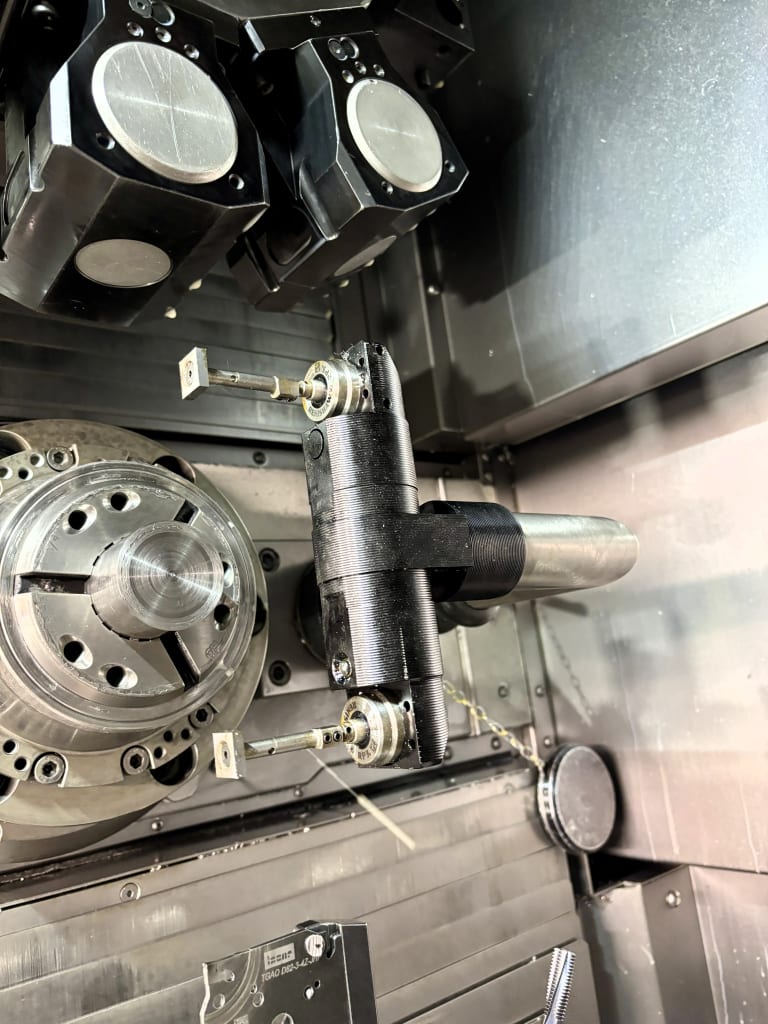

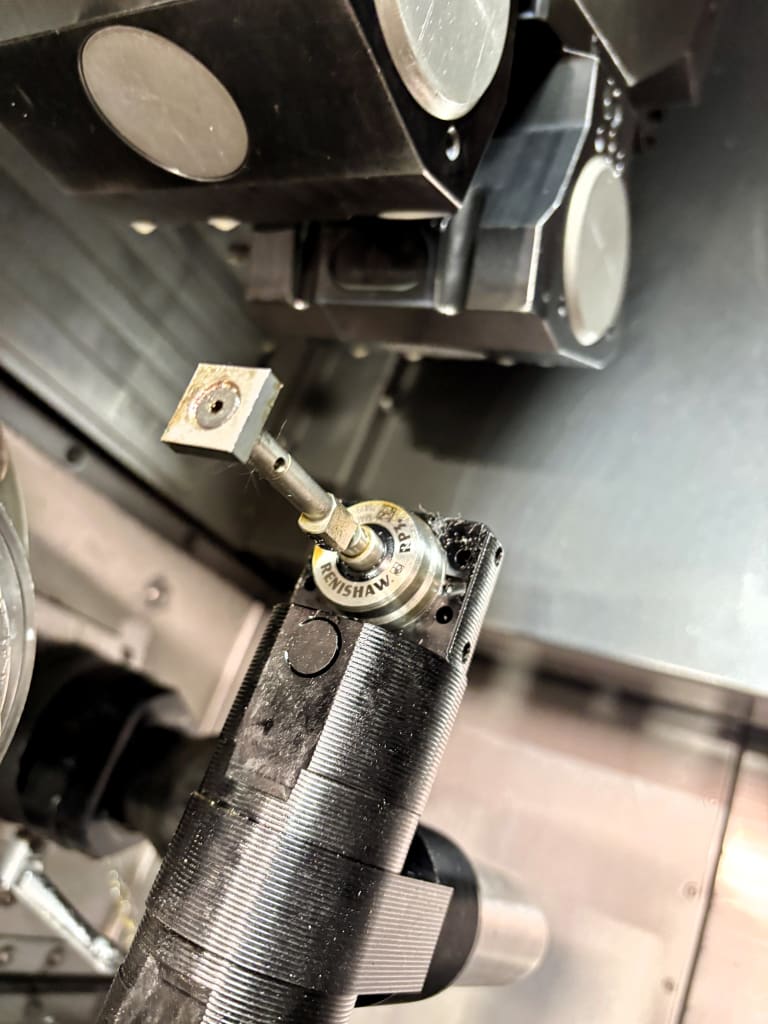

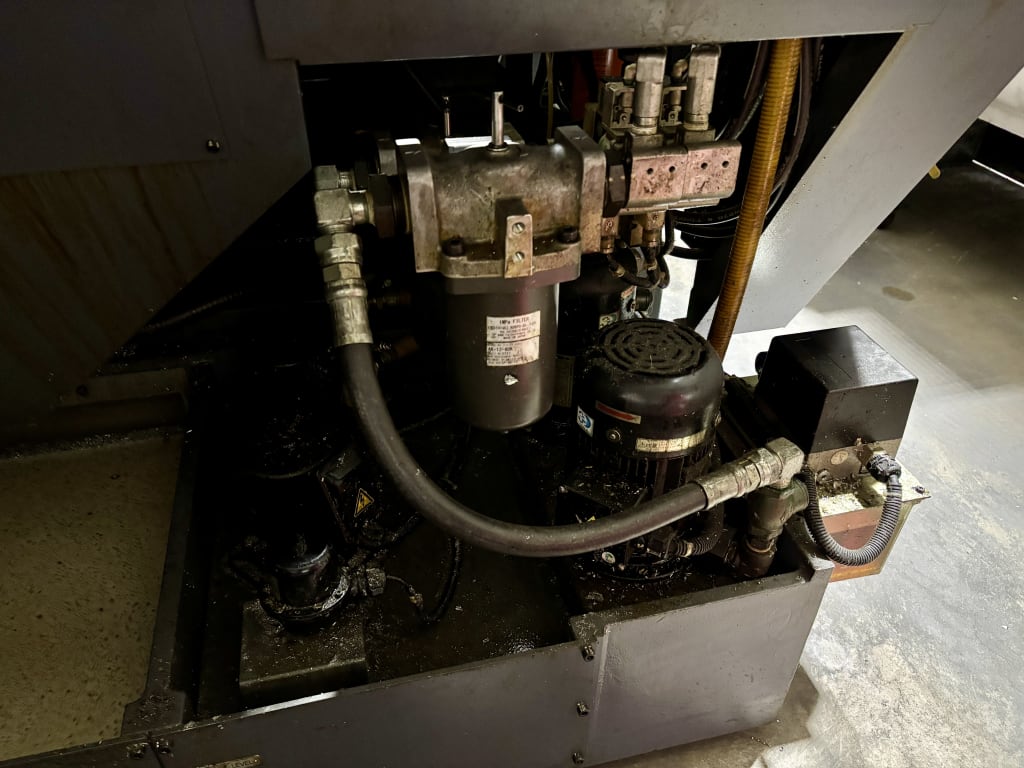

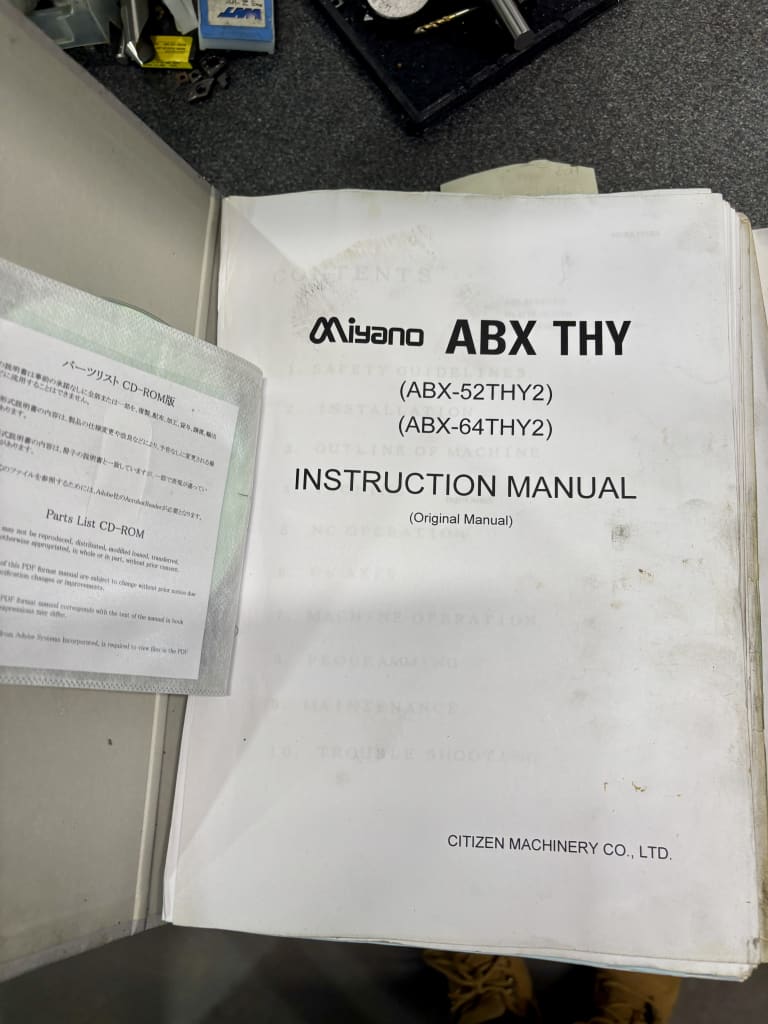

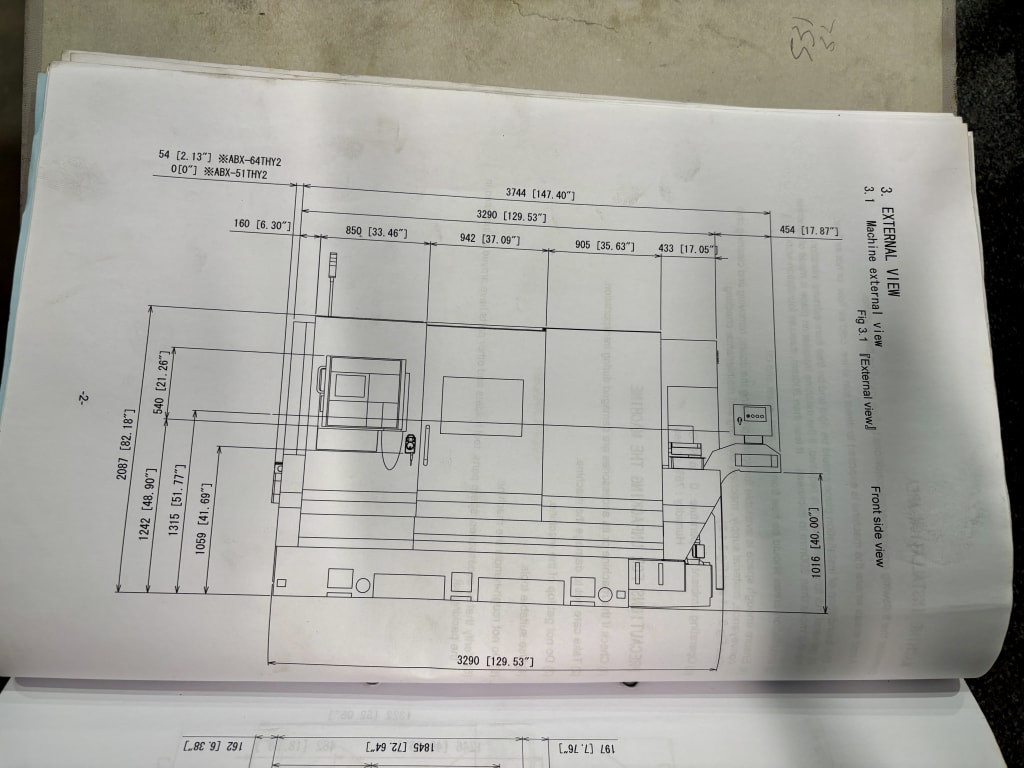

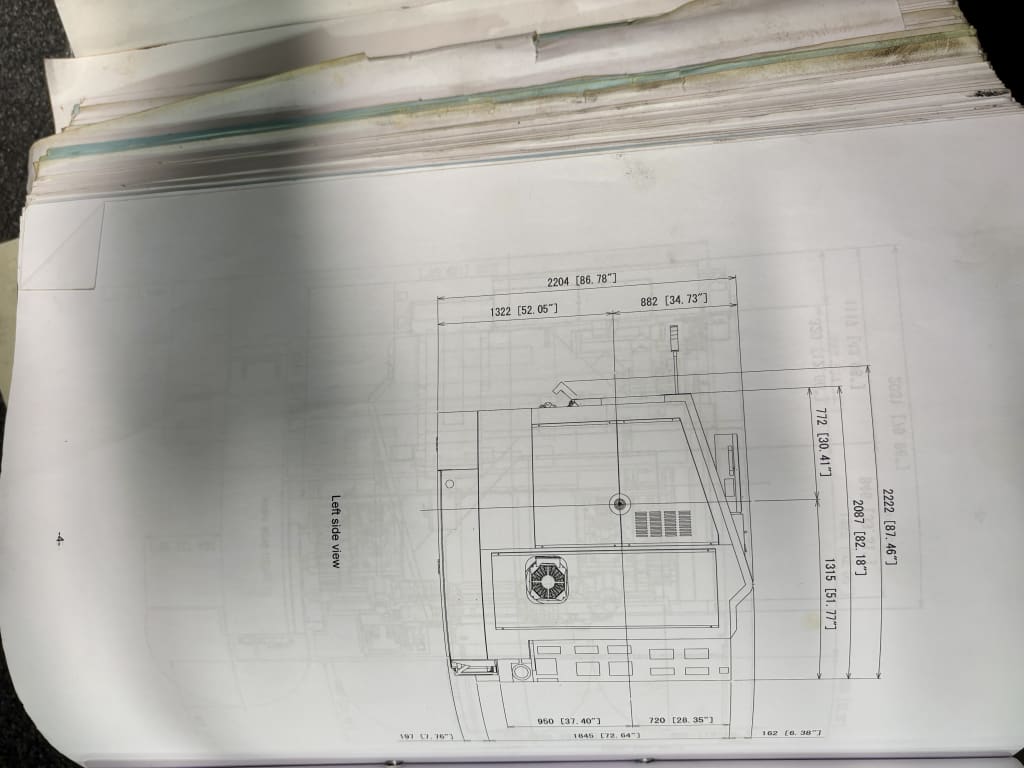

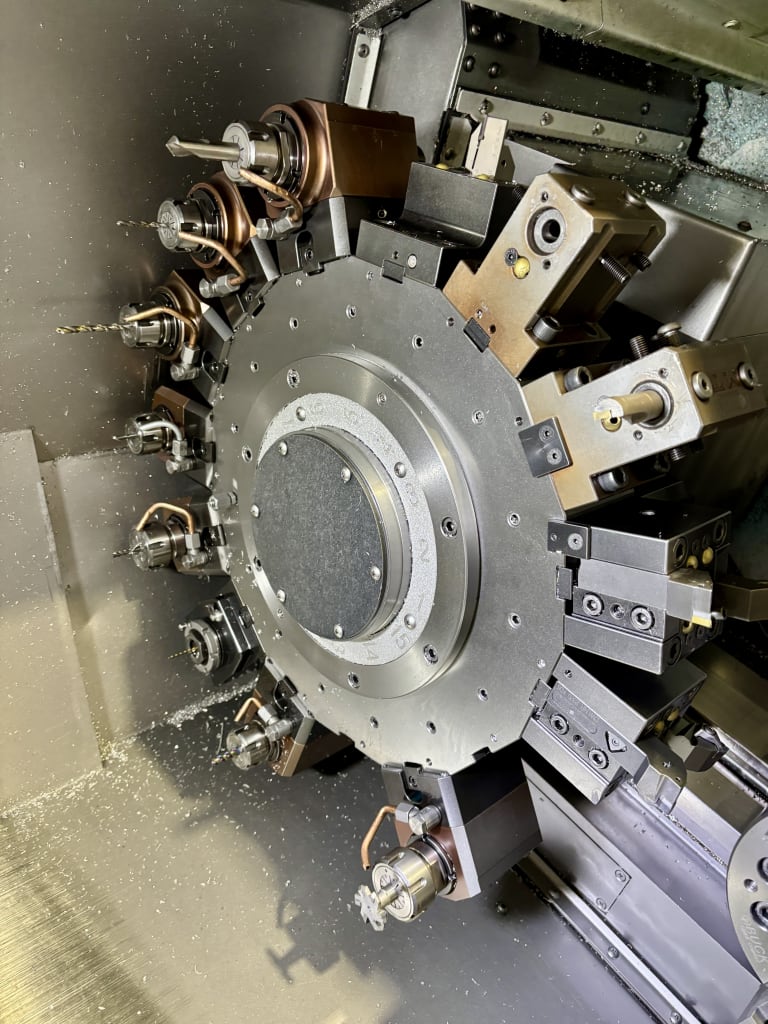

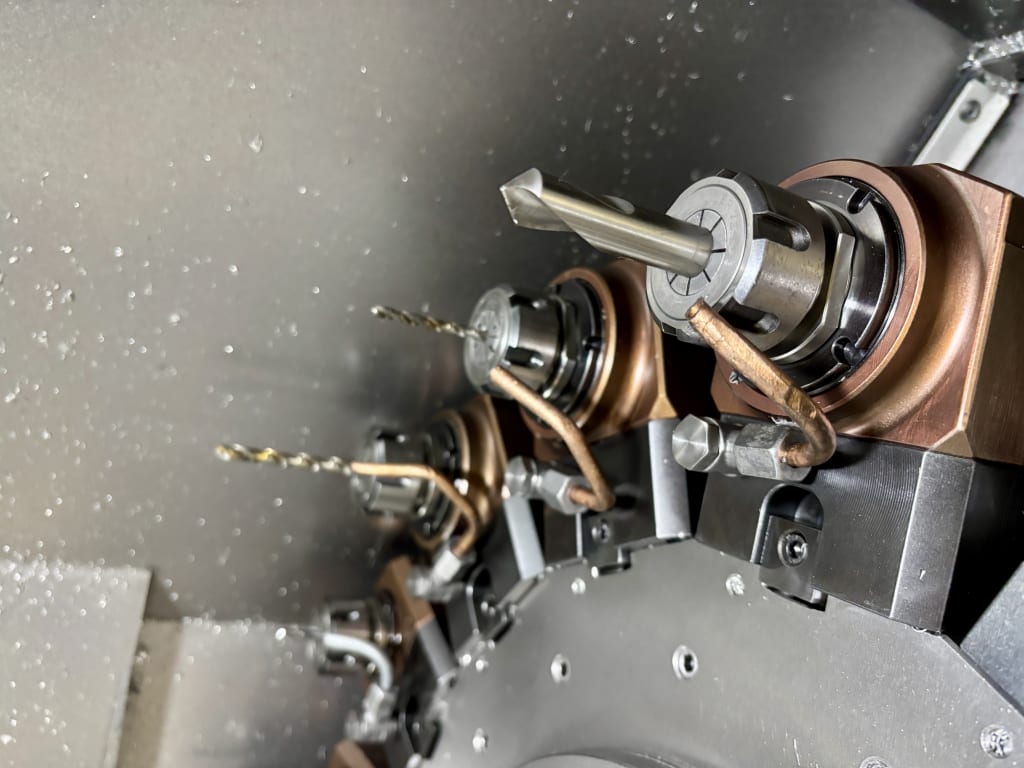

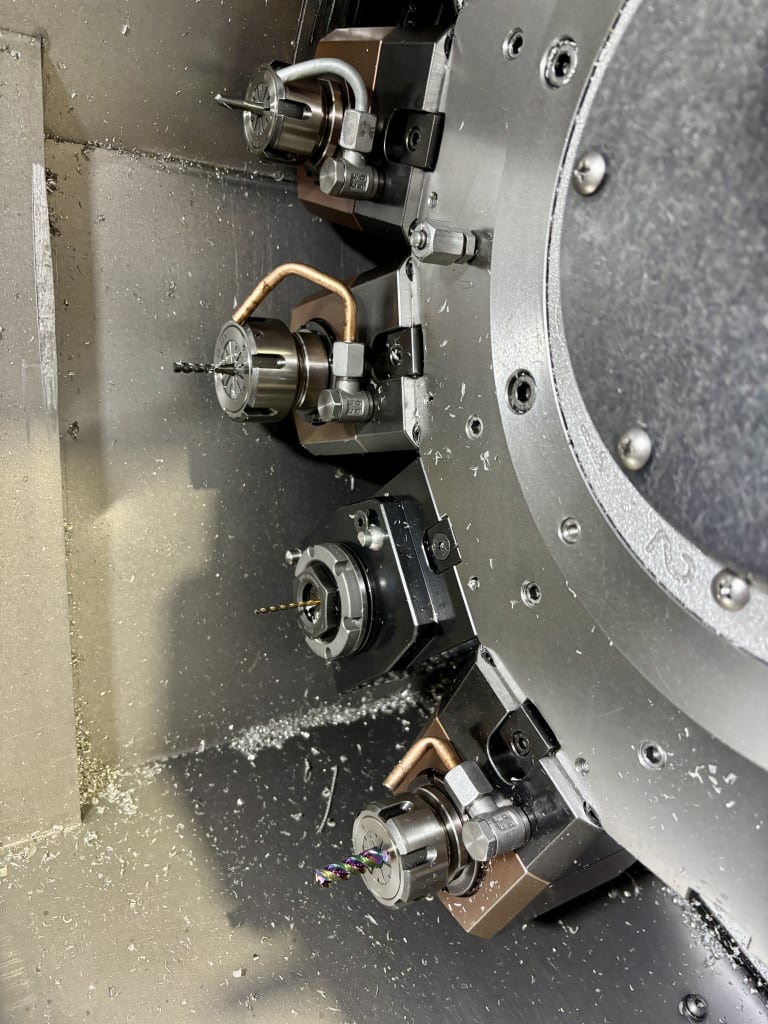

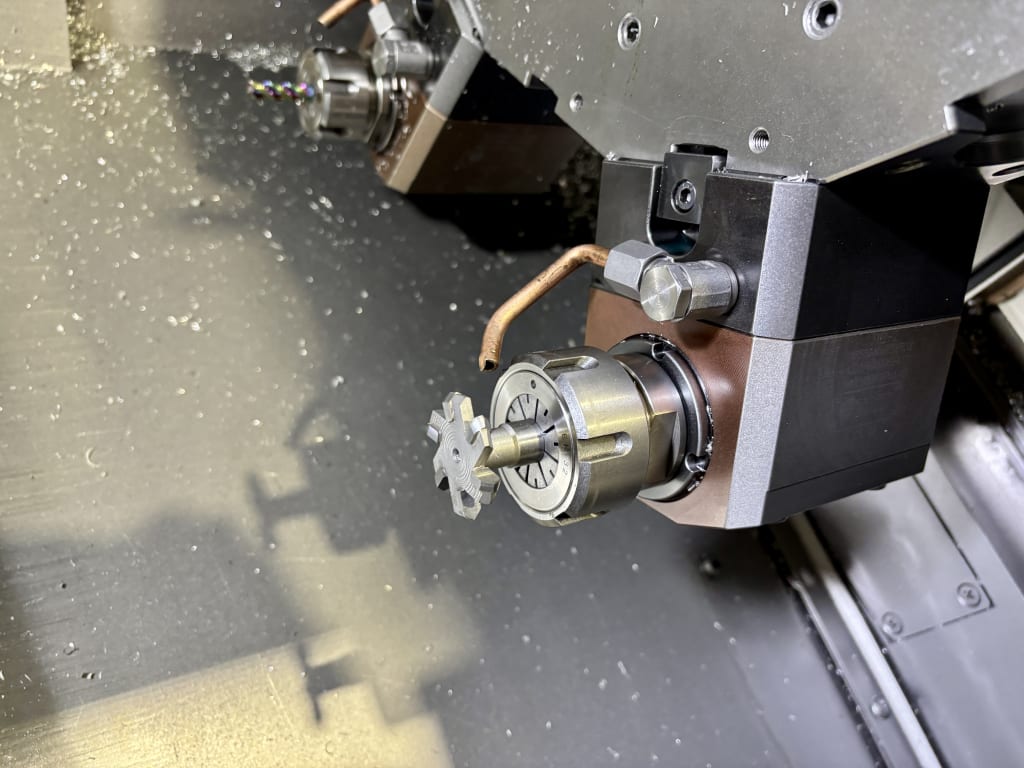

2017 Citizen Miyano ABX-64THY2 Twin Spindle, Triple Turret CNC Lathe With Fanuc Series 31i-B Control & Hydrafeed MSV80

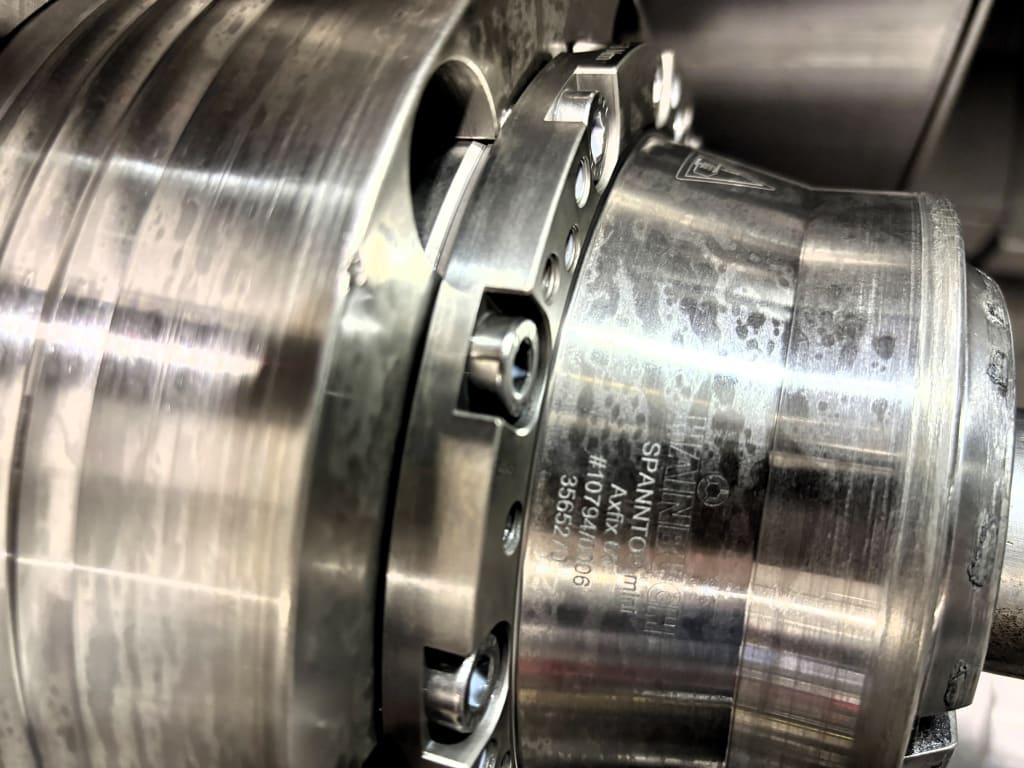

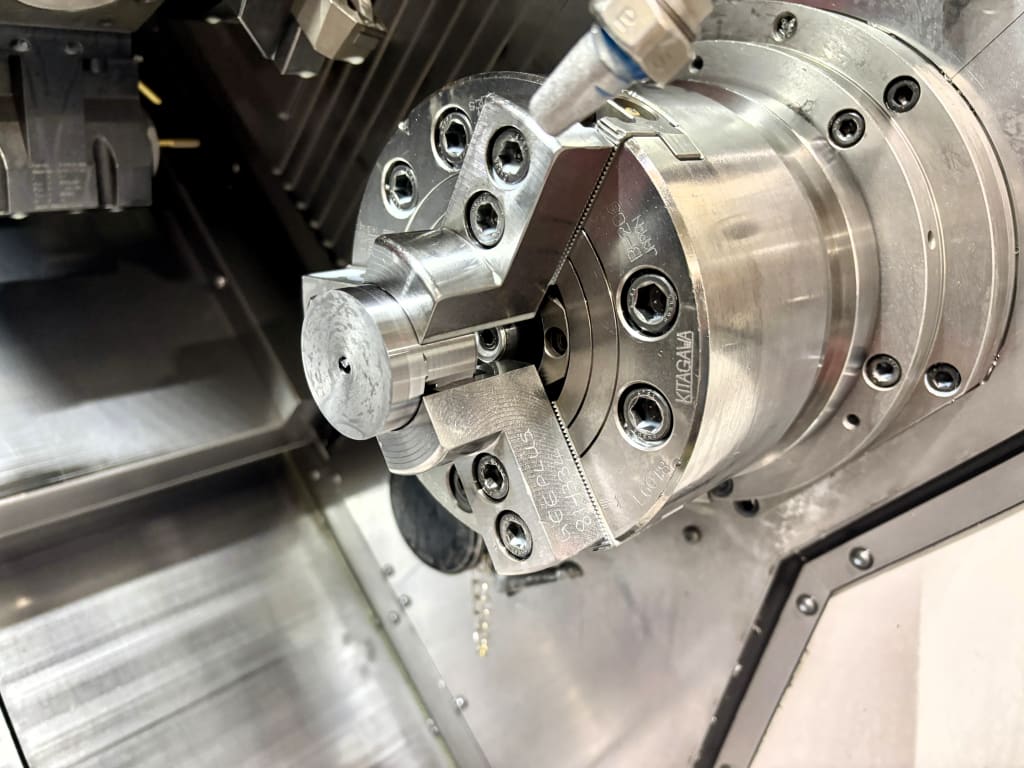

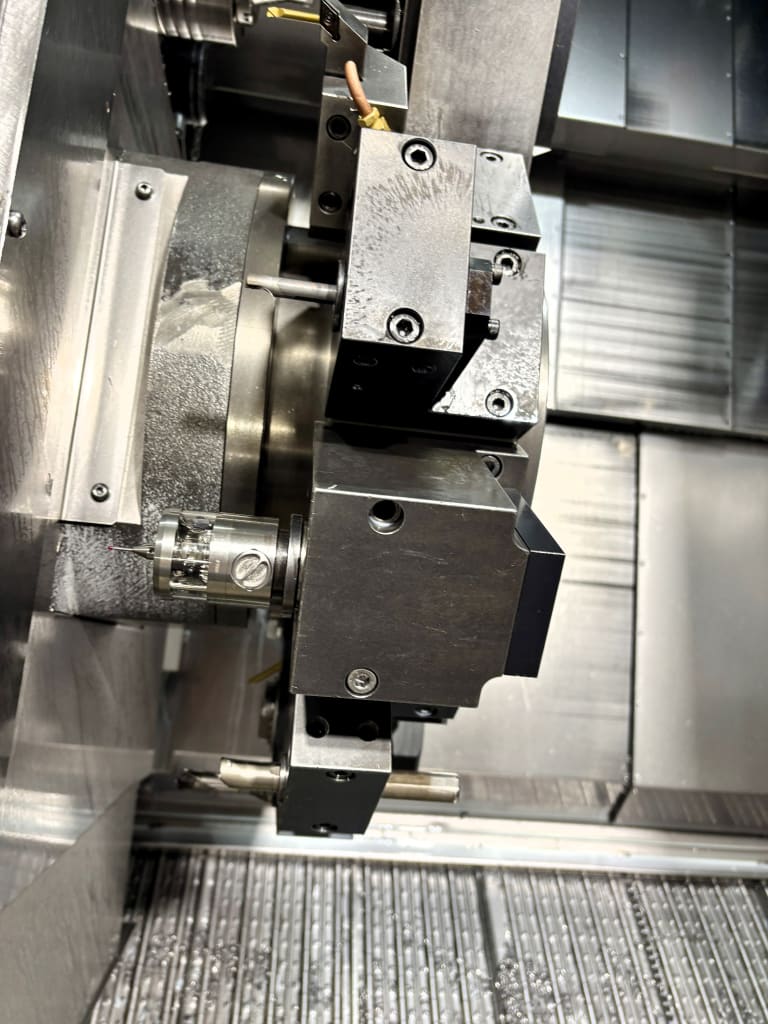

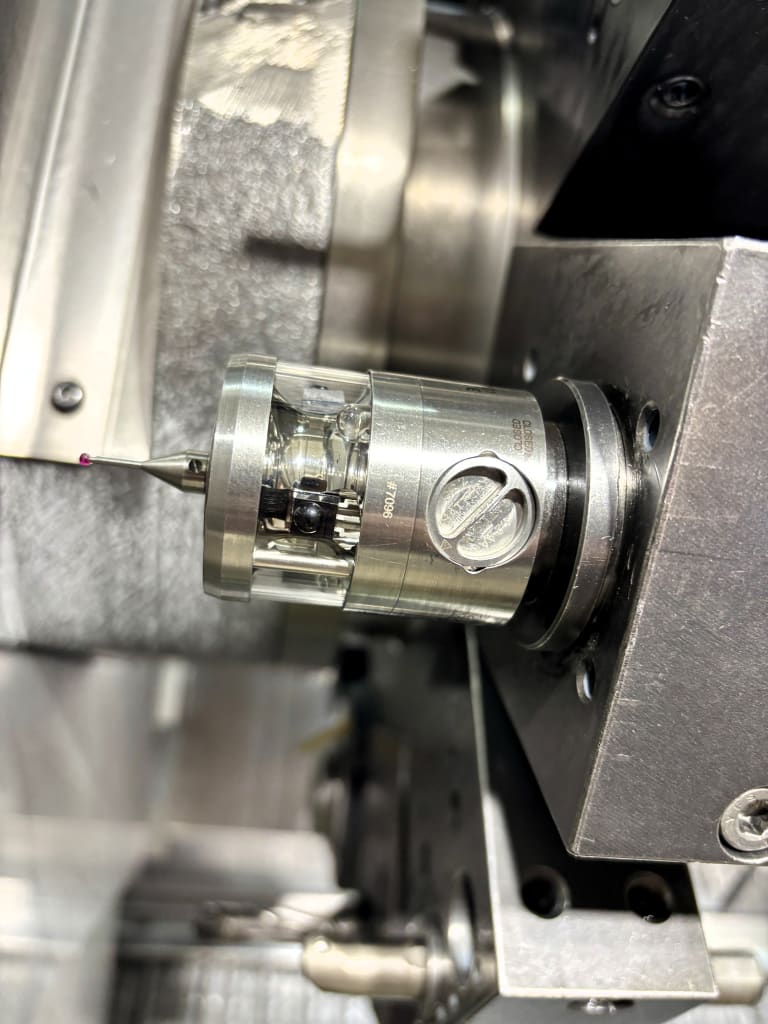

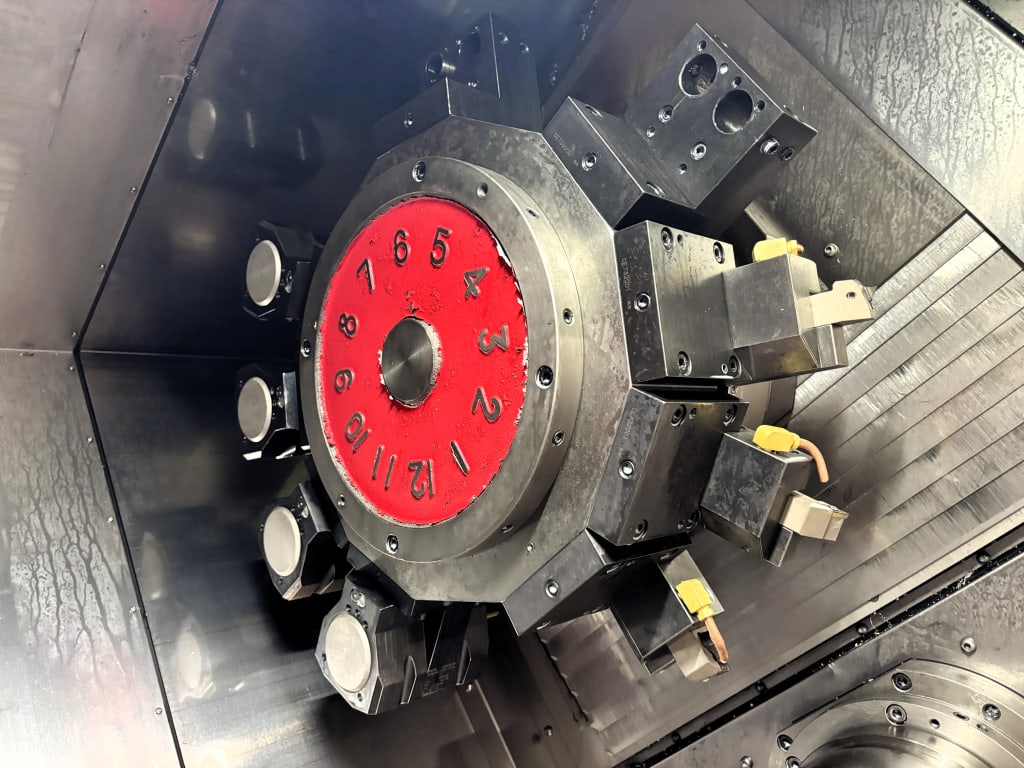

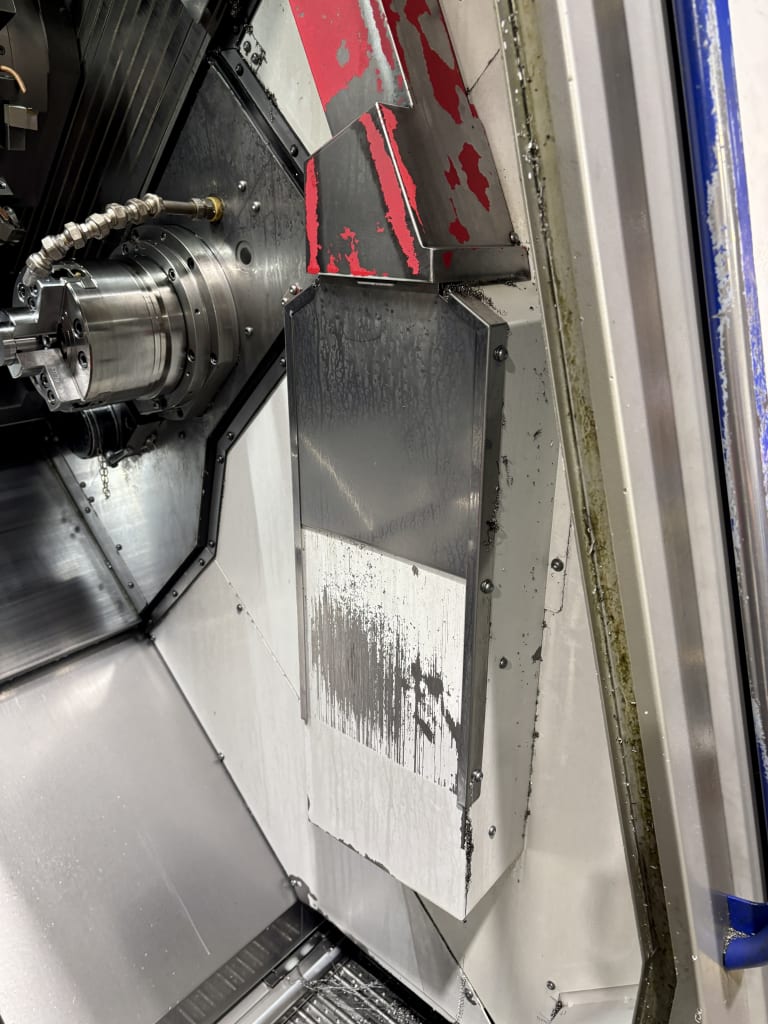

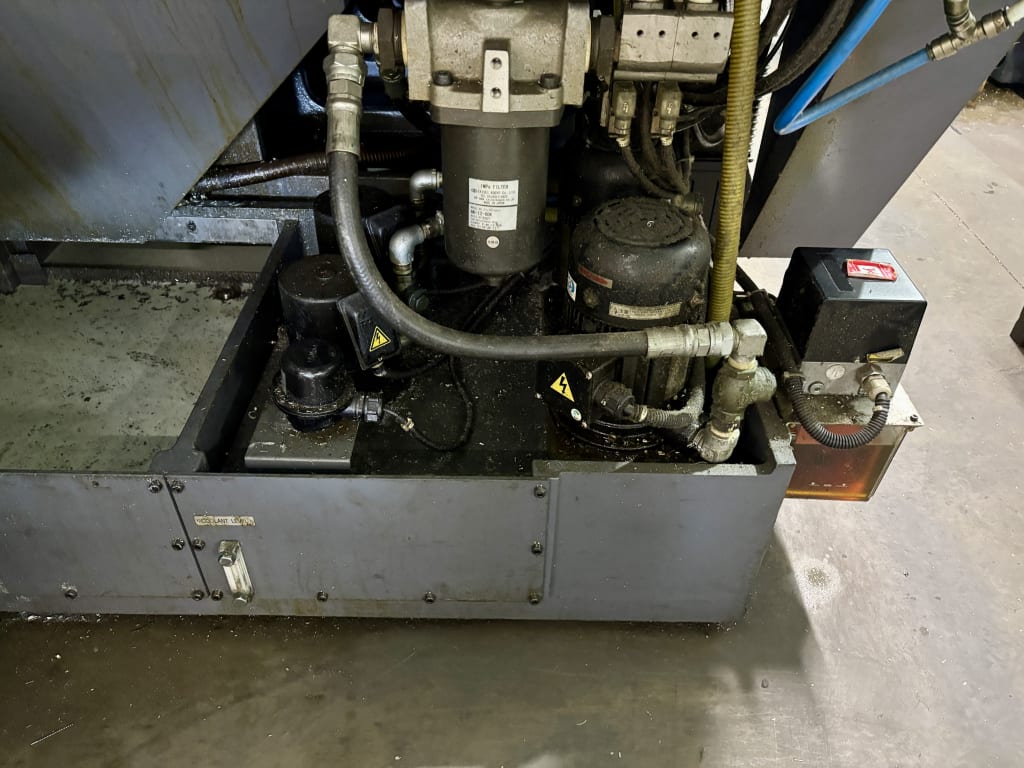

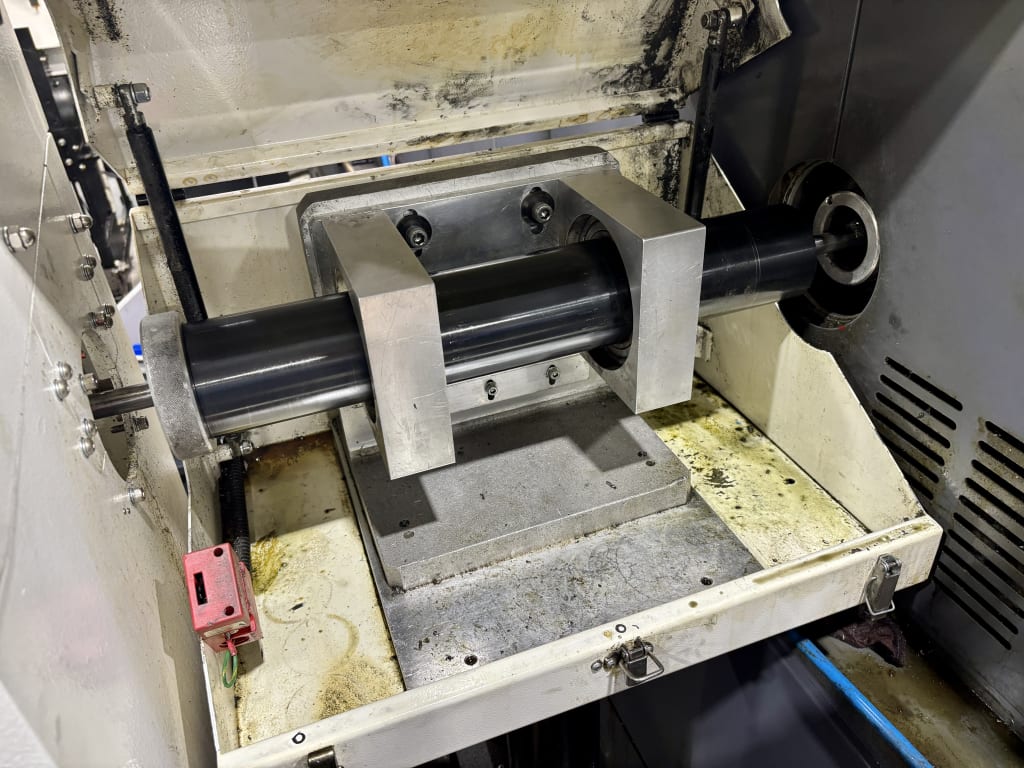

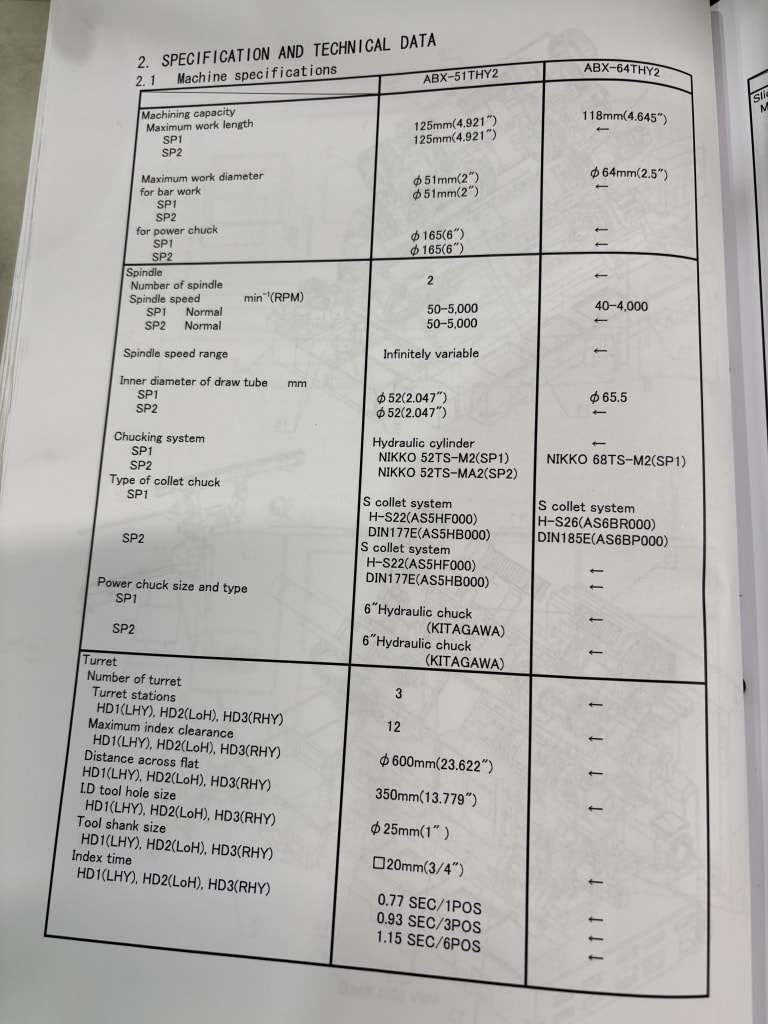

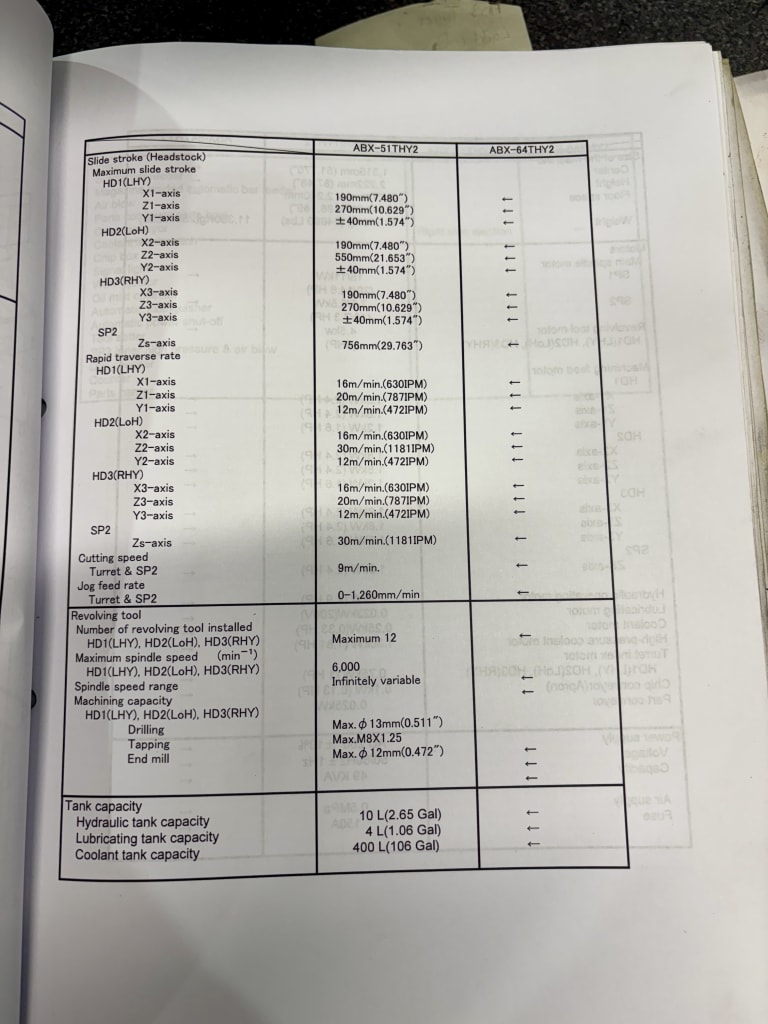

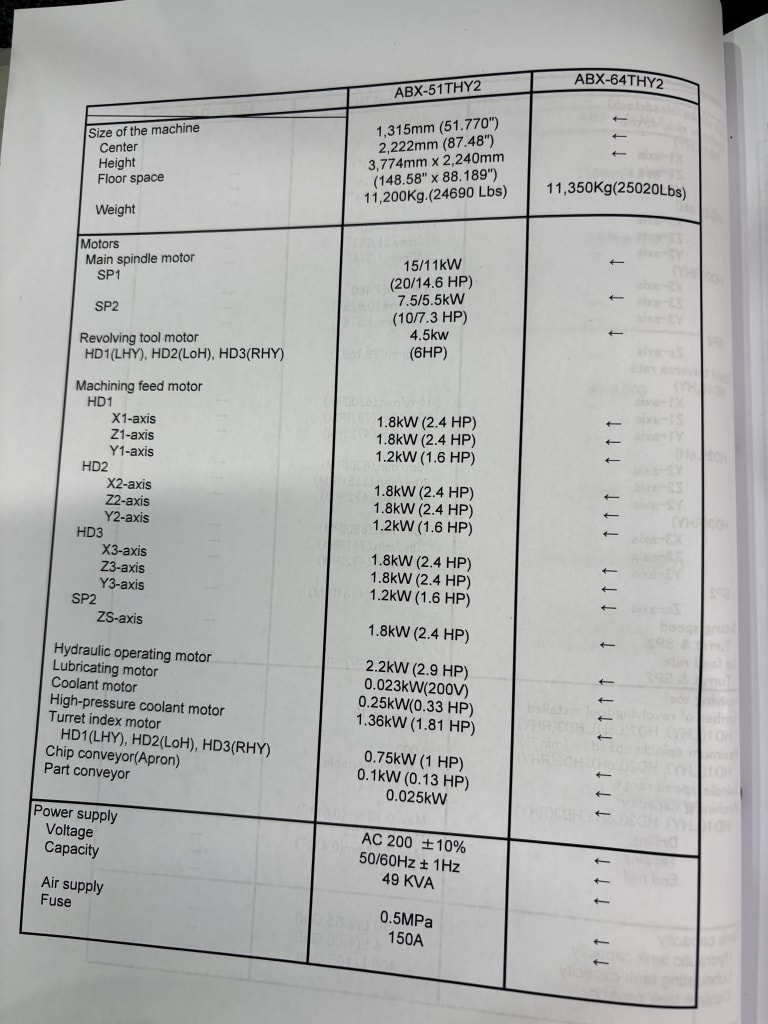

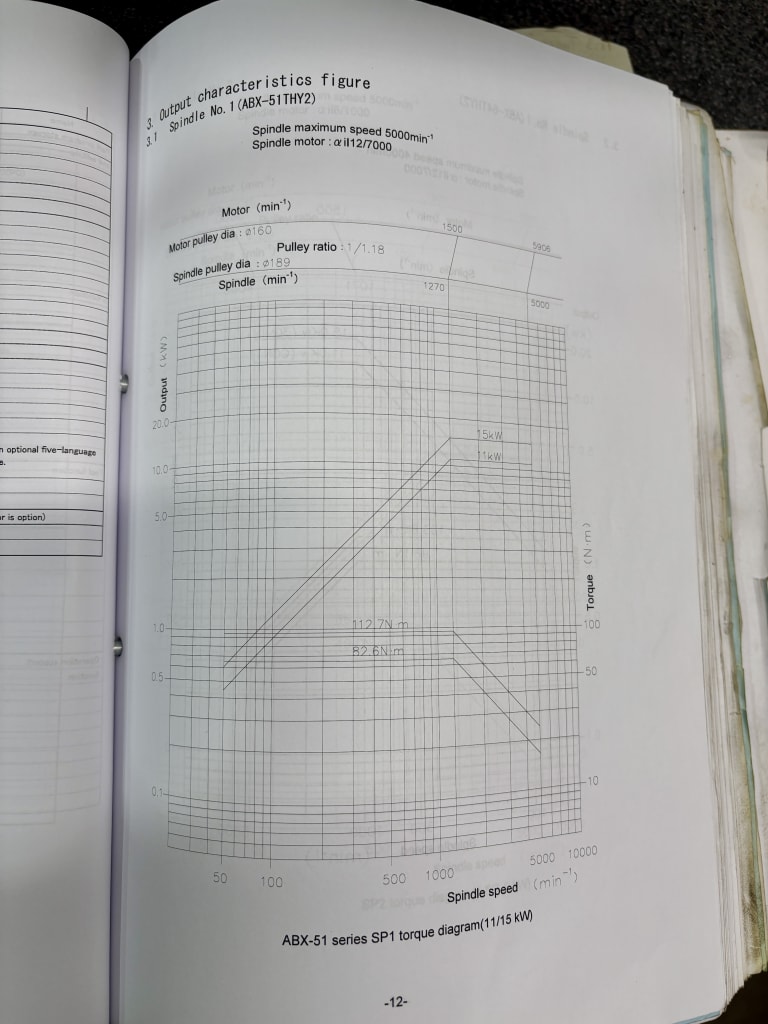

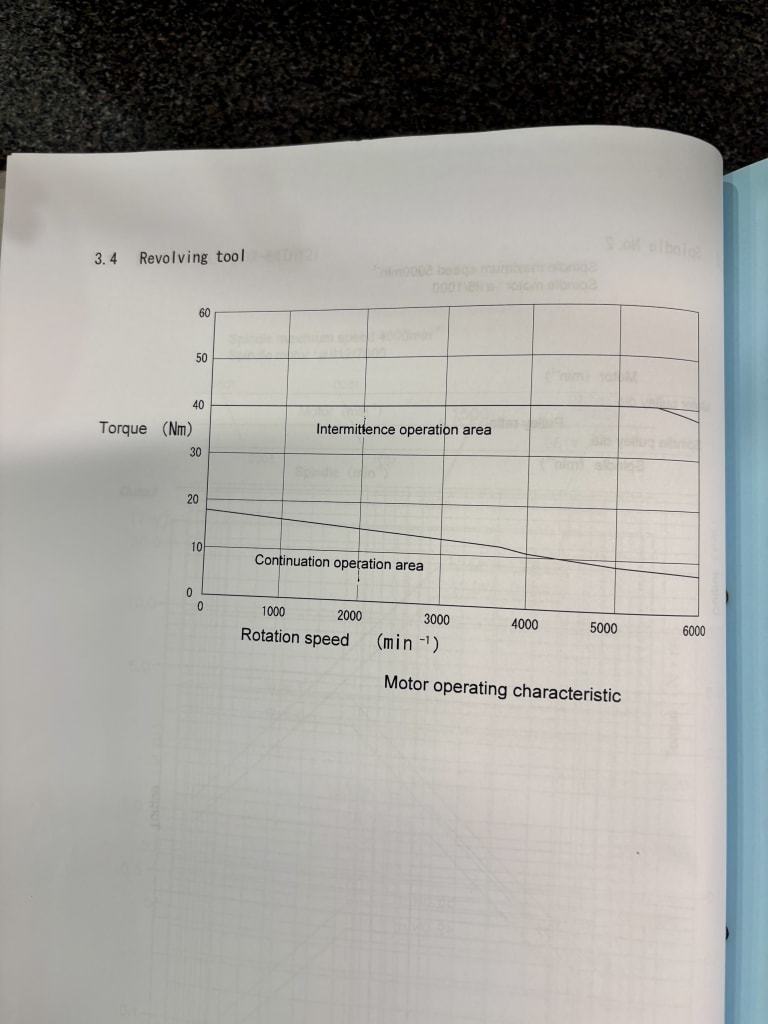

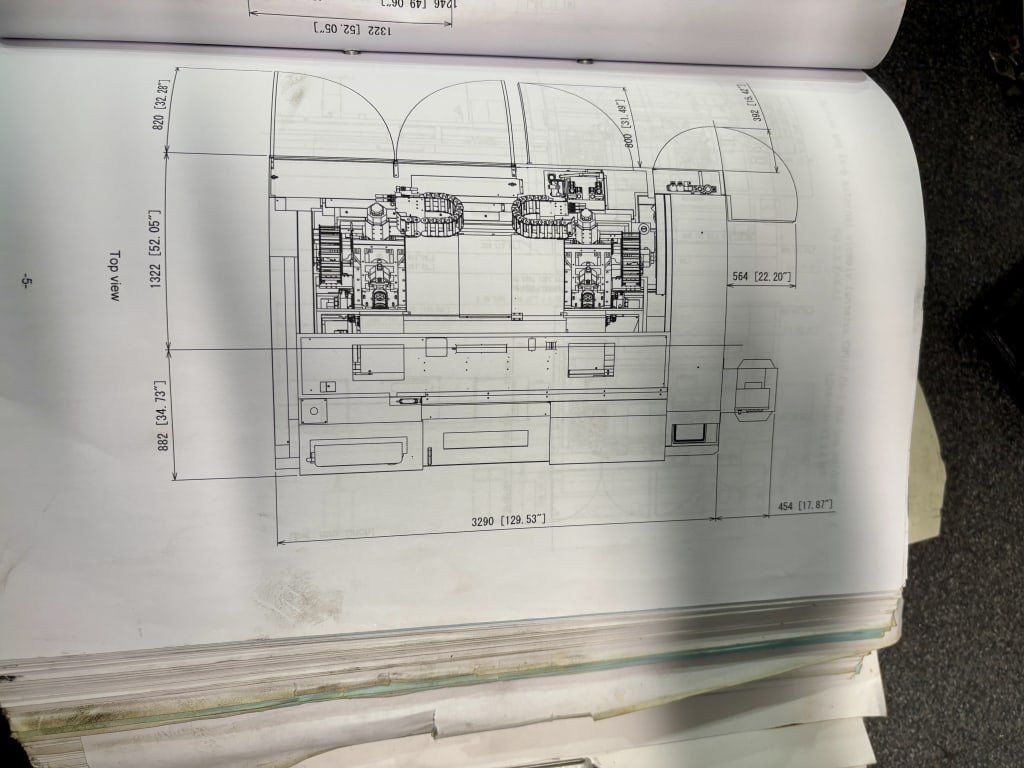

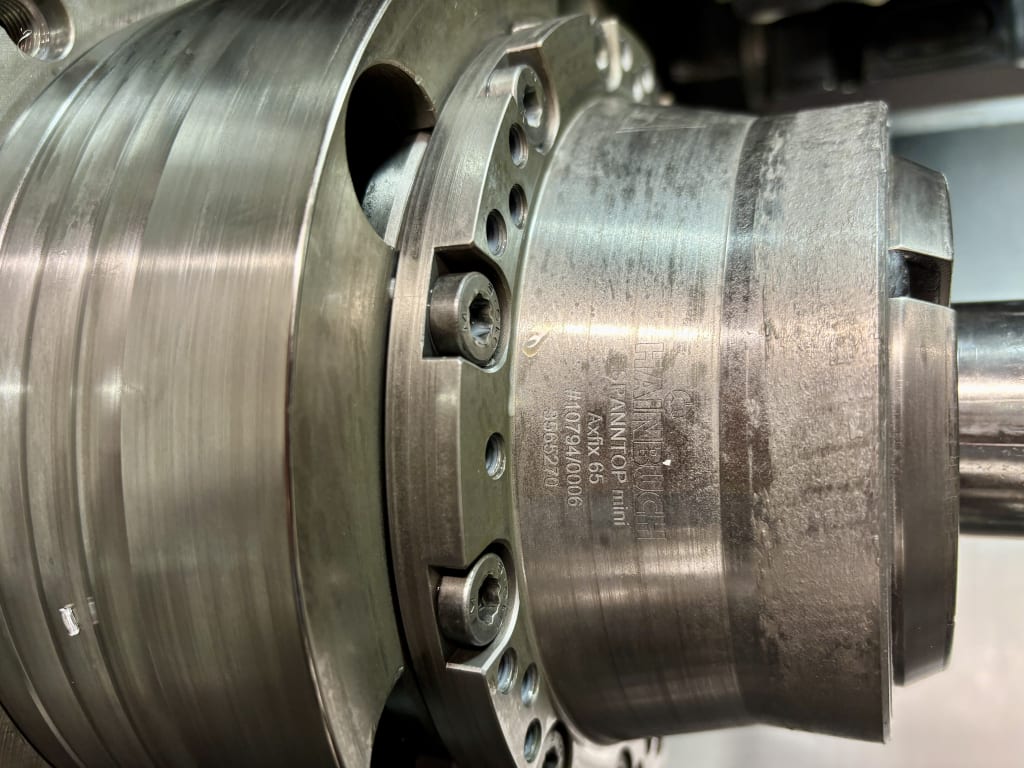

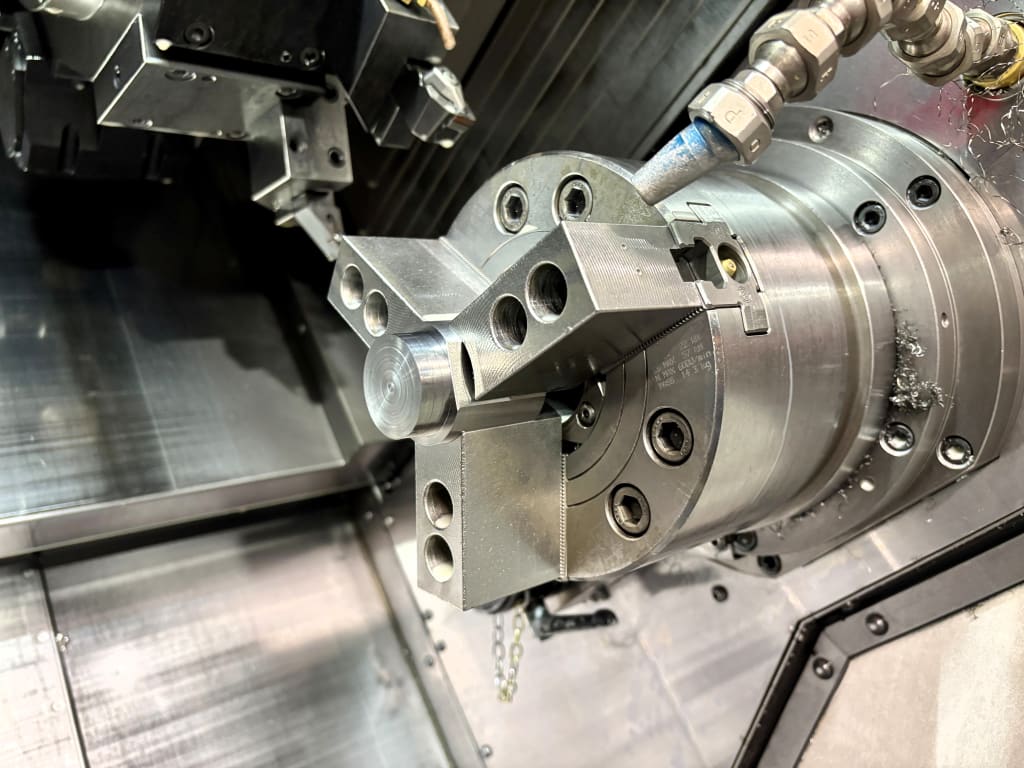

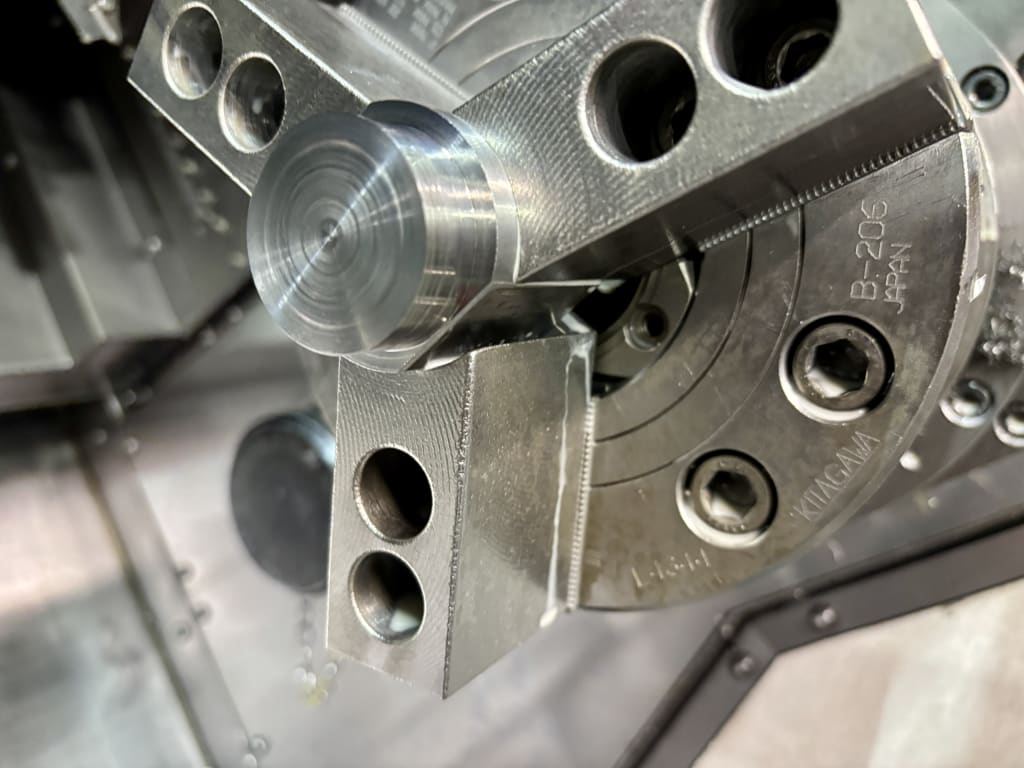

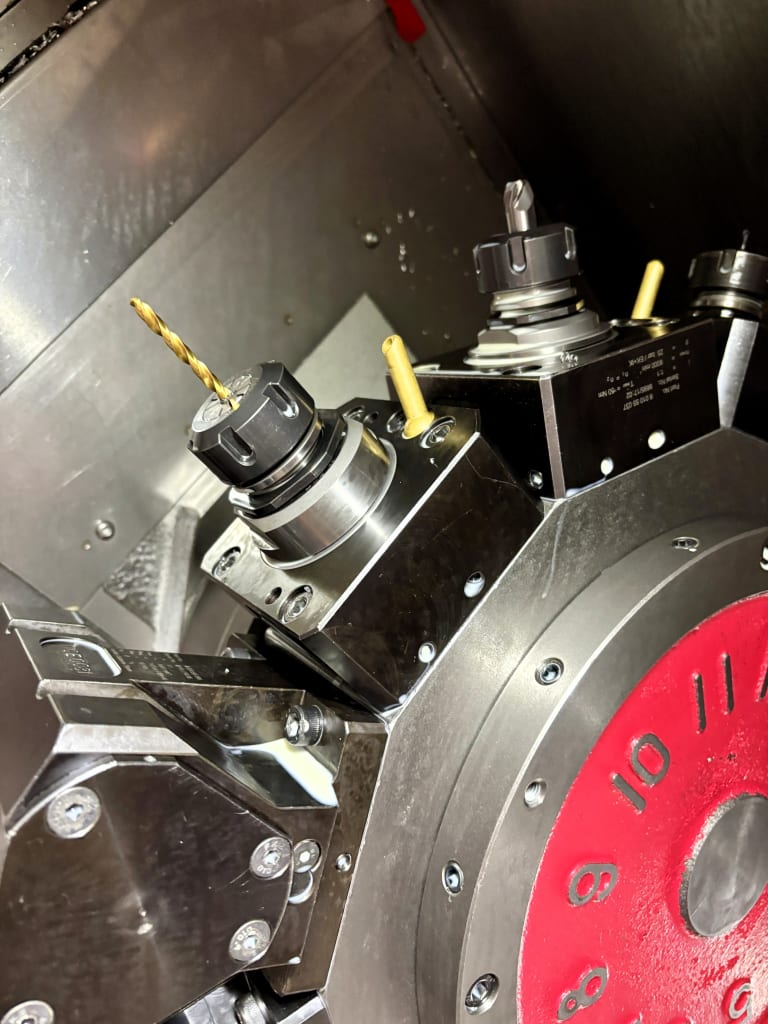

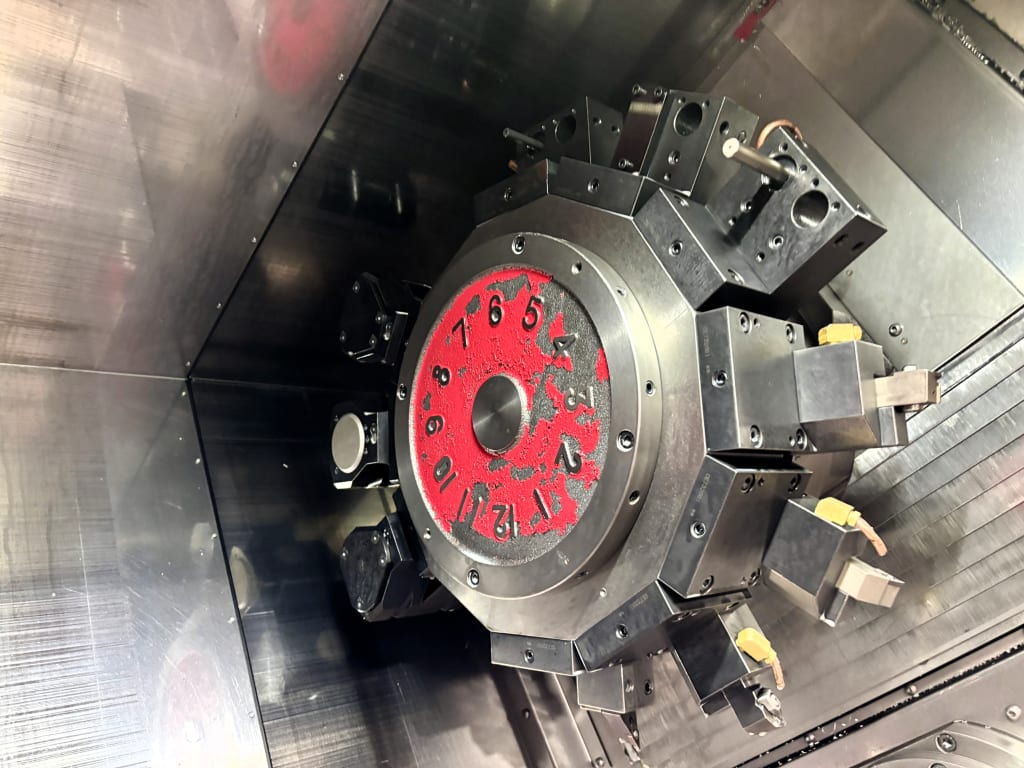

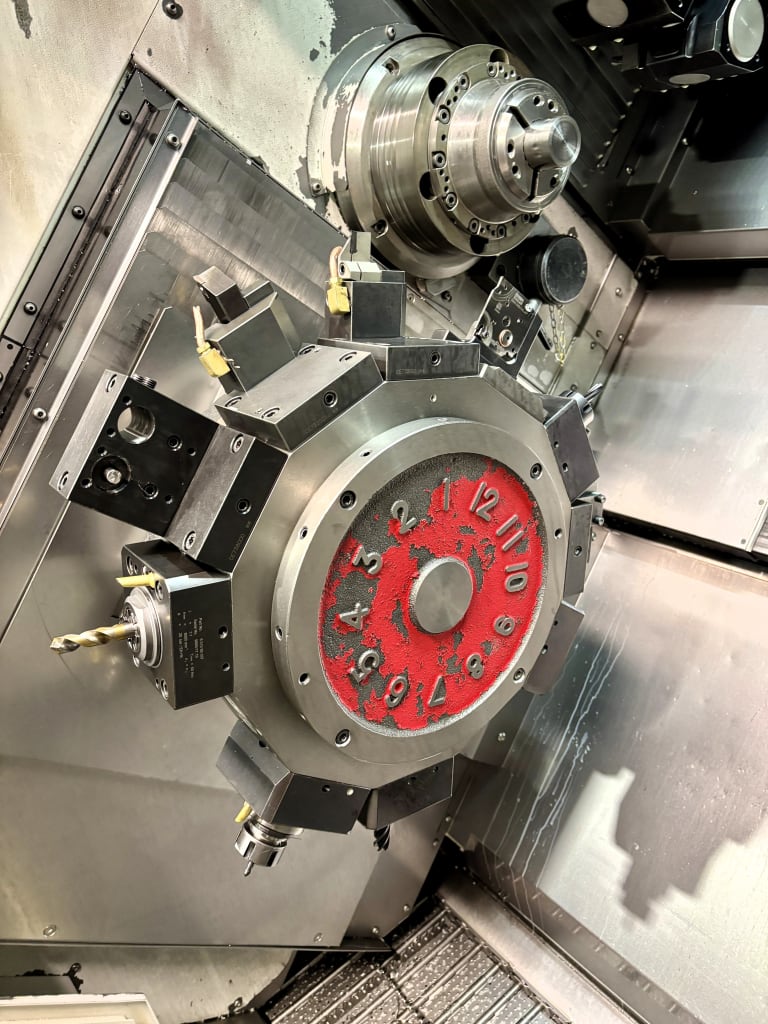

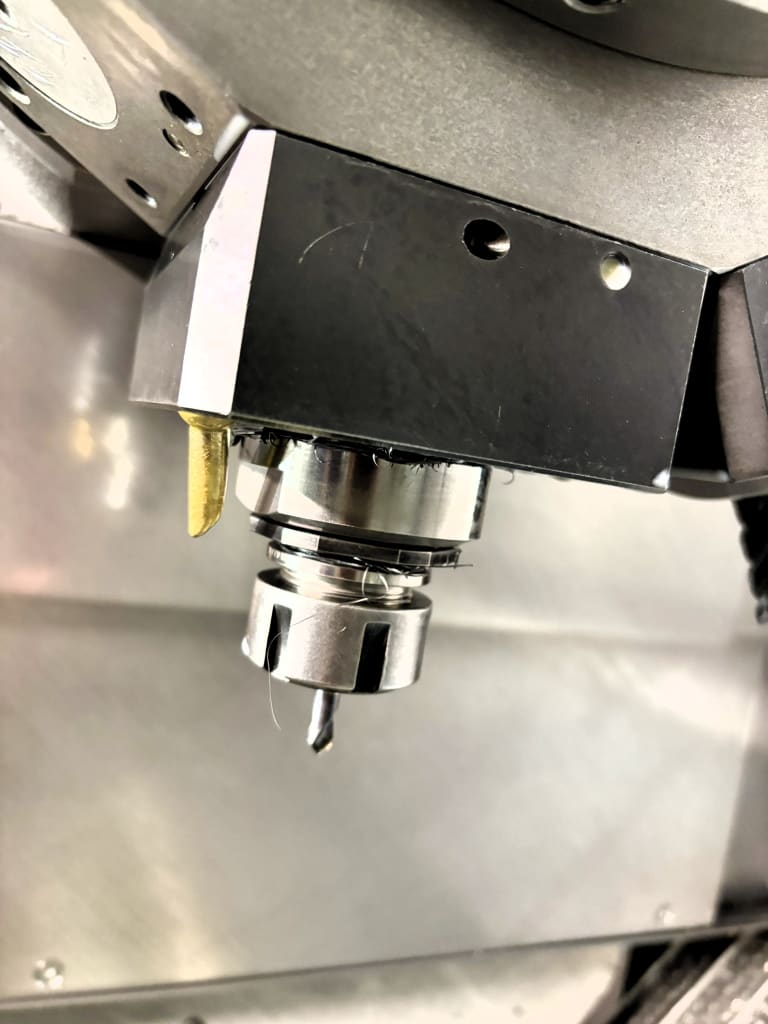

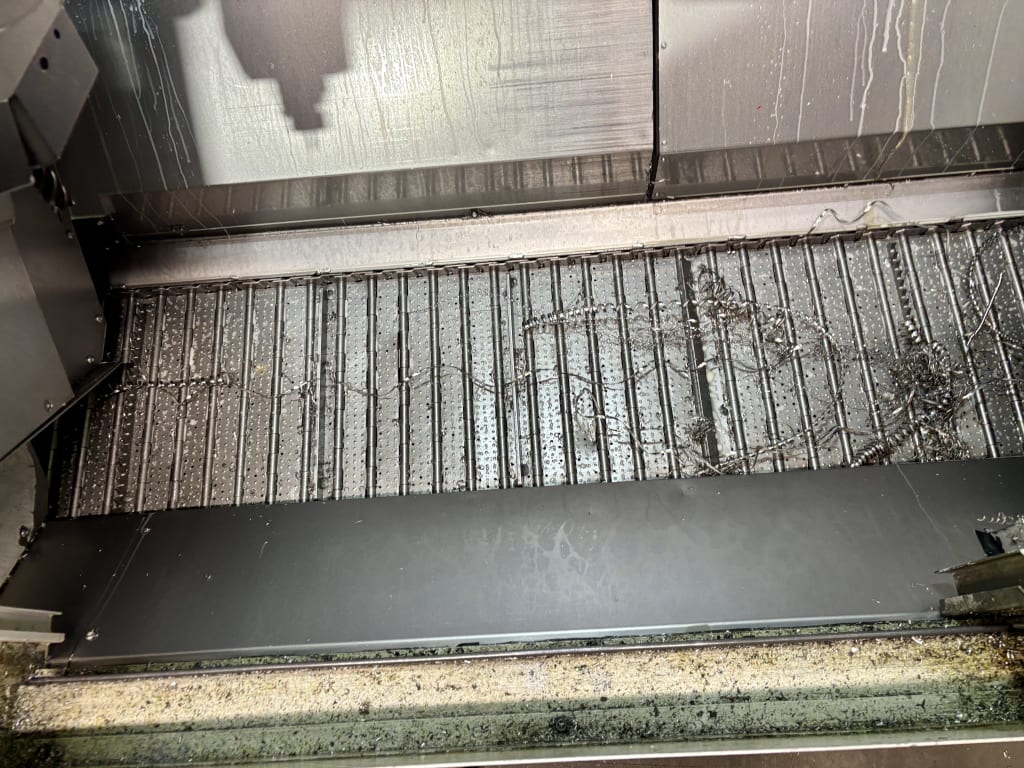

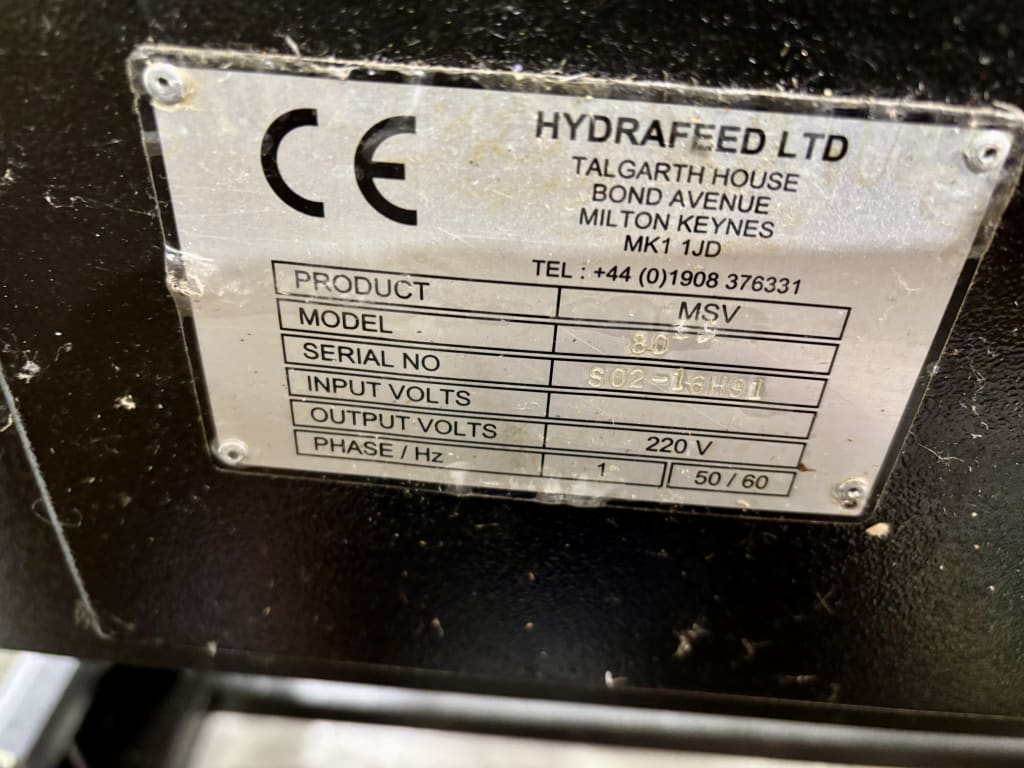

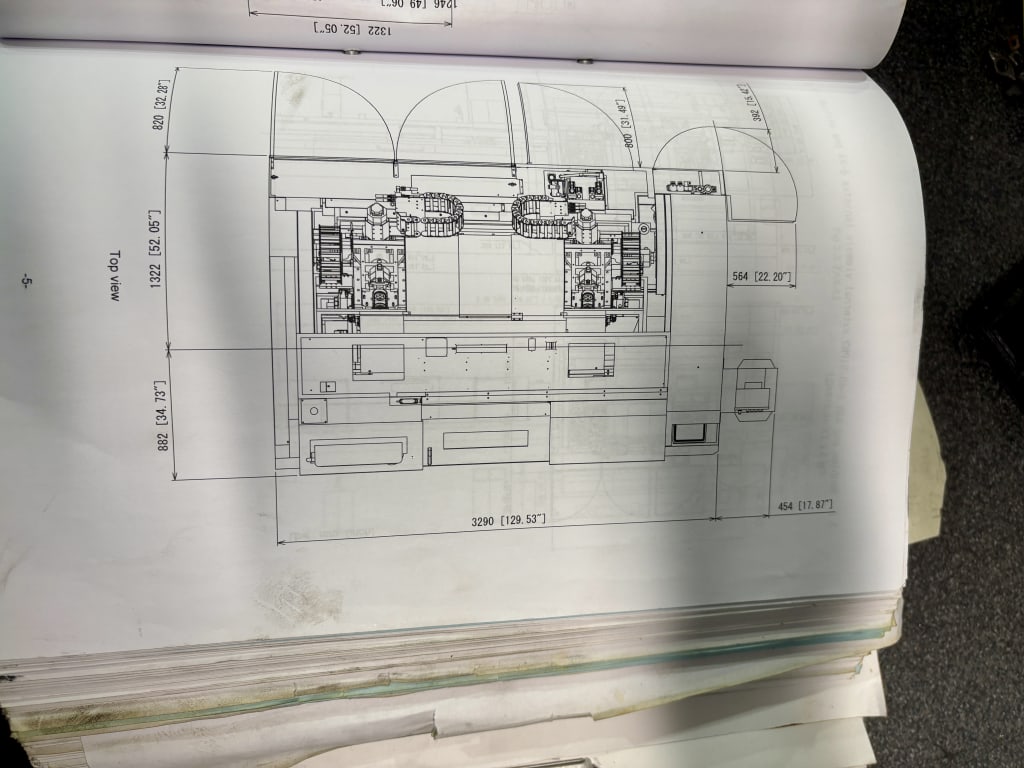

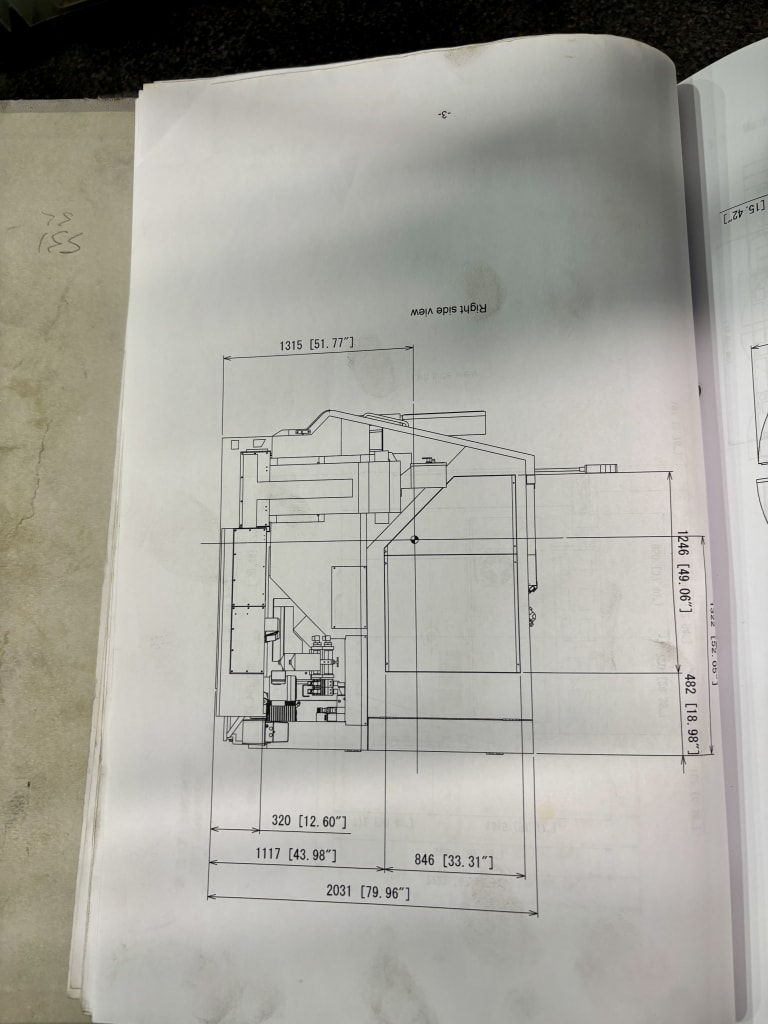

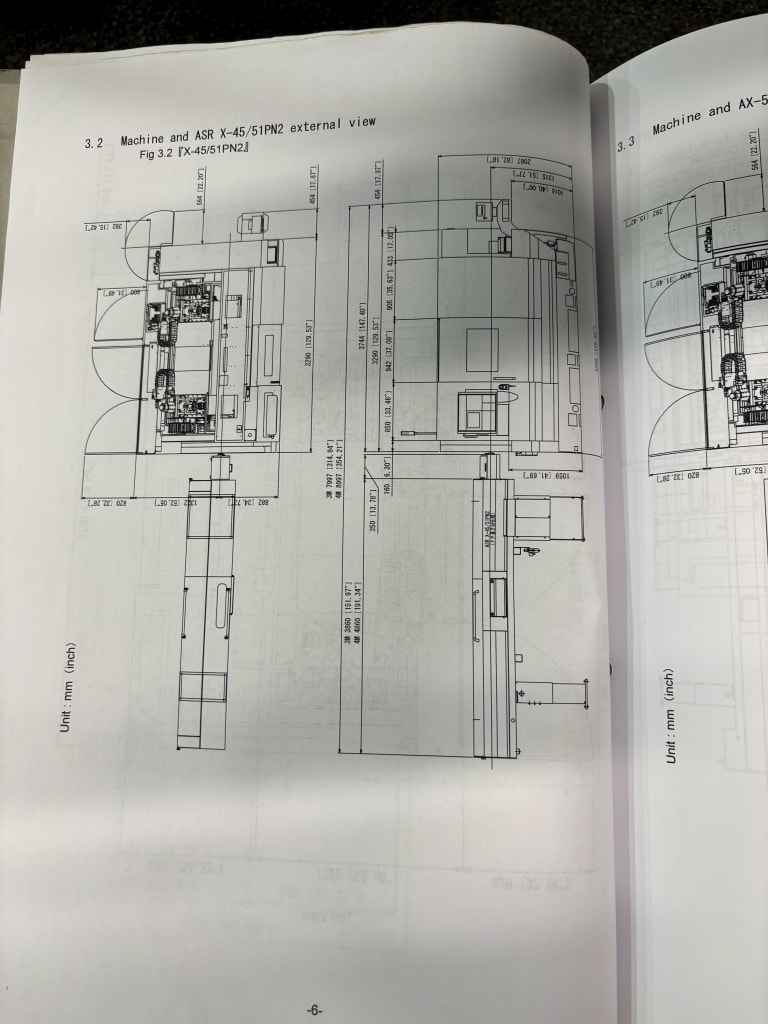

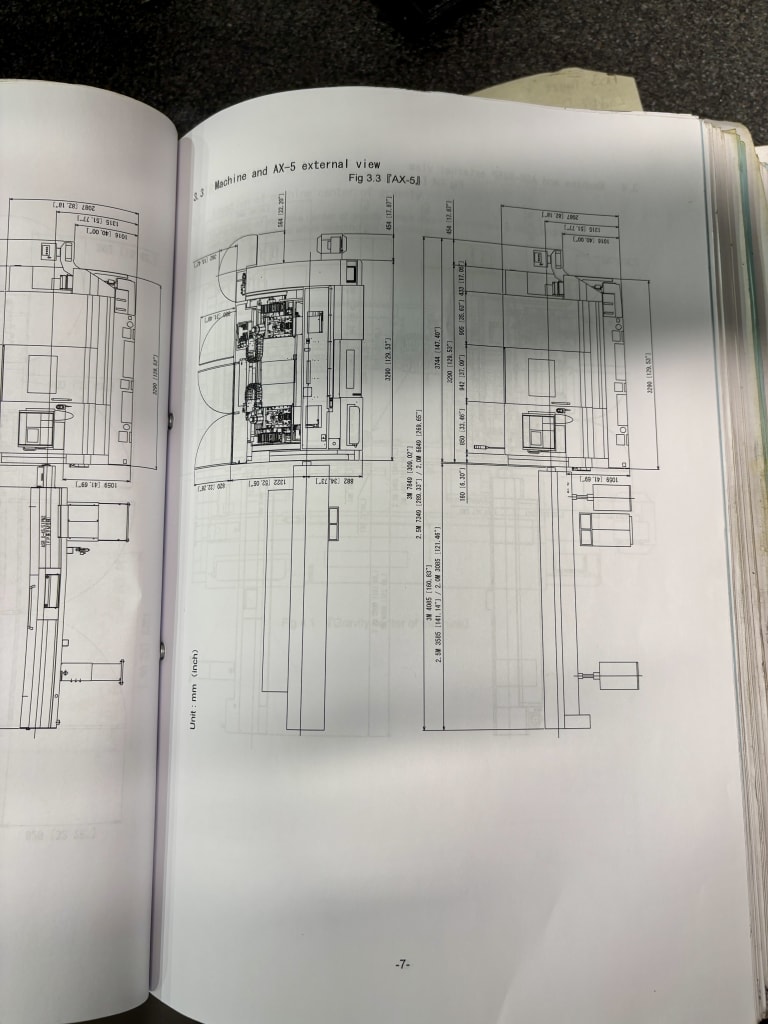

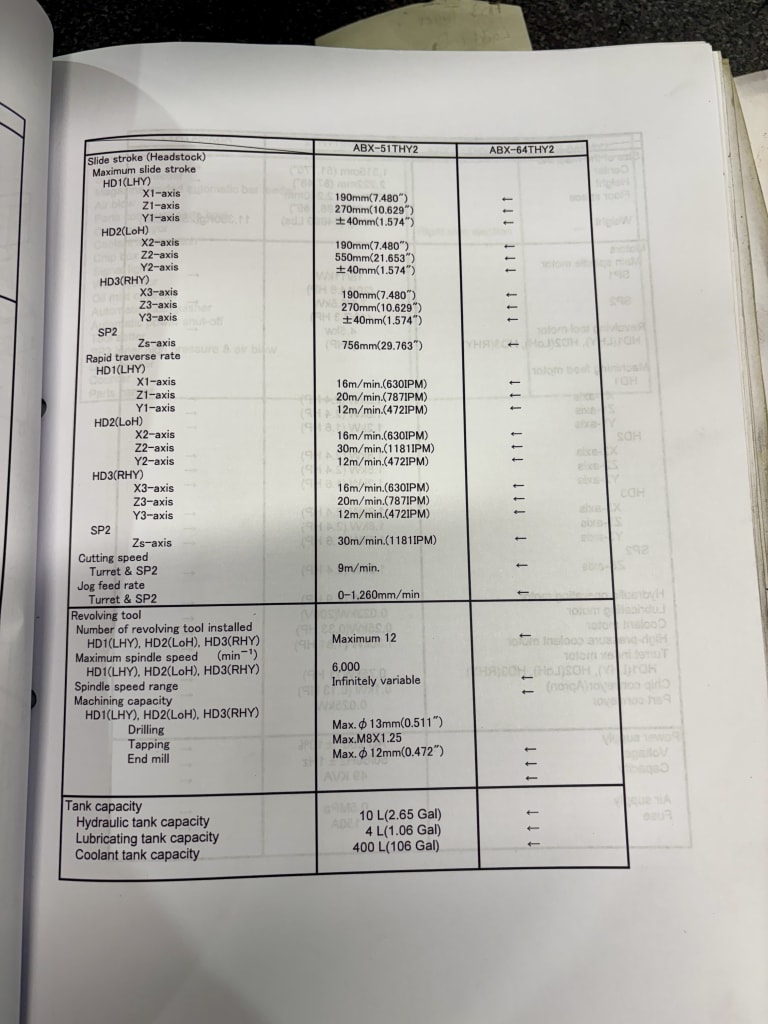

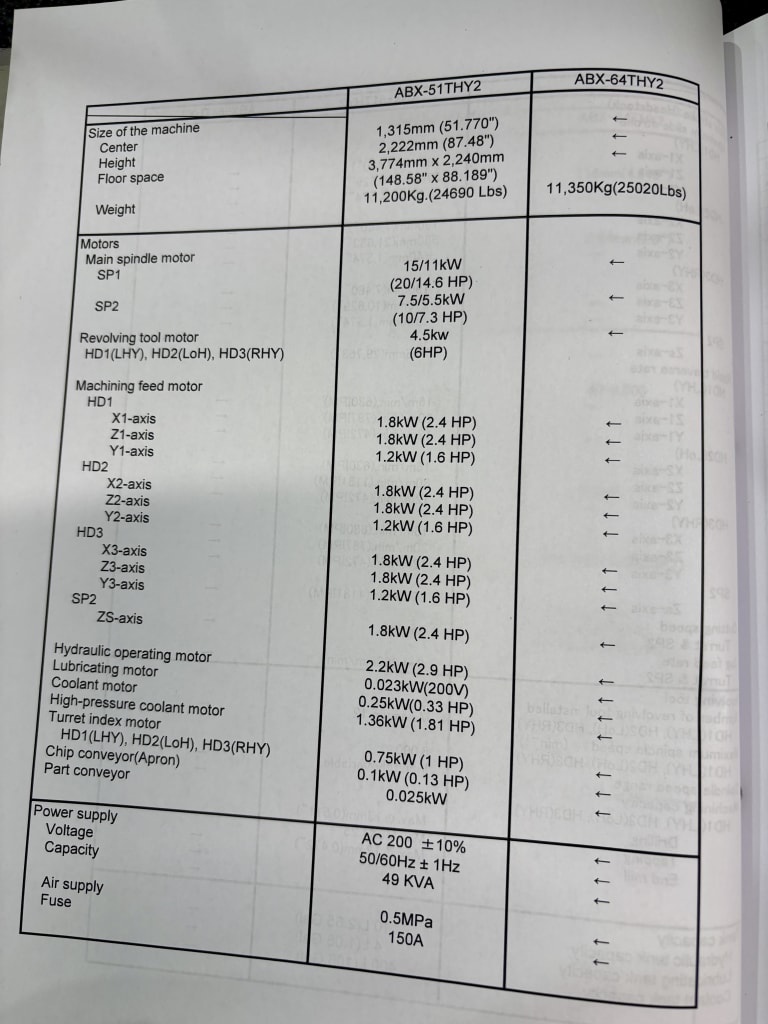

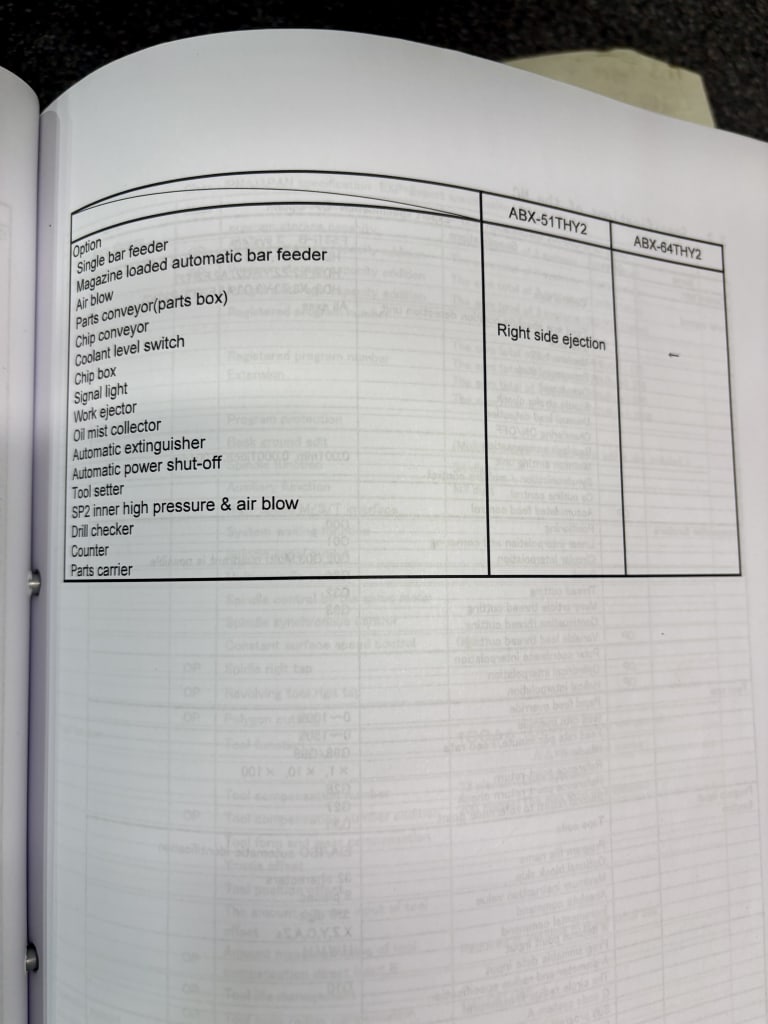

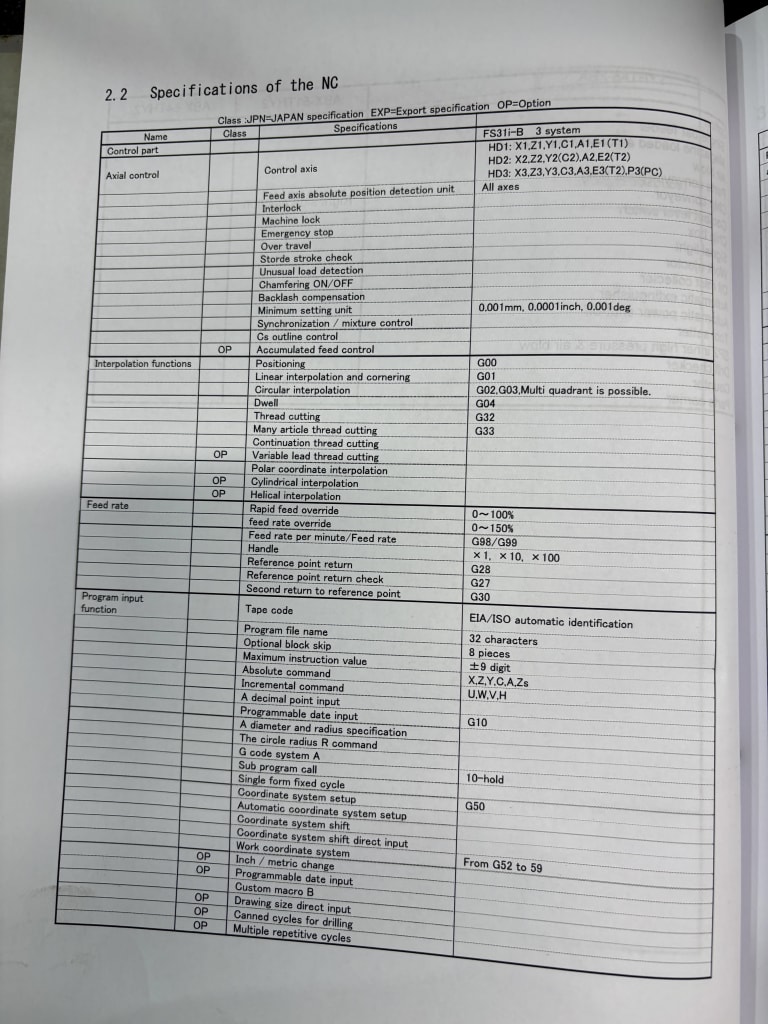

Main Spindle Hainbuch Axfix 65 Collet Chuck. Sub Spindle Kitagawa B-206 Ø152mm 3 Jaw Power Chuck. Maximum Working Length S1=118mm, Sp2=125mm. Maximum Work Ø Bar Work SP1=Ø64mm, SP2=Ø51mm, Maximum Power Chuck Work SP1=Ø165mm, SP2=Ø165mm. Axis Travel Turret 1 'X'=190mm, 'Z'=270mm, 'Y'=±40mm, Turret 2 'X'=190mm, 'Z'=550mm, 'Y'=±40mm, Turret 3 'X'=190mm, 'Z'=270mm, 'Y'= ±40mm, SP2 'Z'=756mm. Spindle Speed Range SP1=40-4,000rpm (15kW Motor), SP2=50-5,000rpm (7.5kW Motor). Inner Ø Of Draw Tube SP1=Ø65.5, SP2=Ø52mm. 3- 12 Position Turrets, Turning Shank Dimension 20 x 20mm, Boring Bar Sleeve Ø25/40mm, Turret Index Time 0.25sec/Per Position. Rapid Traverse Turret 1 'X'=16m/min, 'Z'=30m/min, 'Y'=12m/min, Turret 2 'X'=16m/min, 'Z'=20m/min, 'Y'=12m/min, Turret 3 'X'=16m/min, 'Z'=20m/min, 'Y'=12m/min, SP1 'Z'=30m/min. Number Of Driven Tool Position 36 (12 x 3 Turrets), Driven Tooling Maximum Speed 6,000rpm (4.5kW Motor), Maximum Ø20mm Drilling, Maximum M14 x 2 Tapping, Maximum Ø20mm End Mill. Hydrafeed MSV80 Bar Feeder Length 2,180mm. S/No. CP0061 (2017). Hydrafeed S/No.S02-17G113. - LOT 2

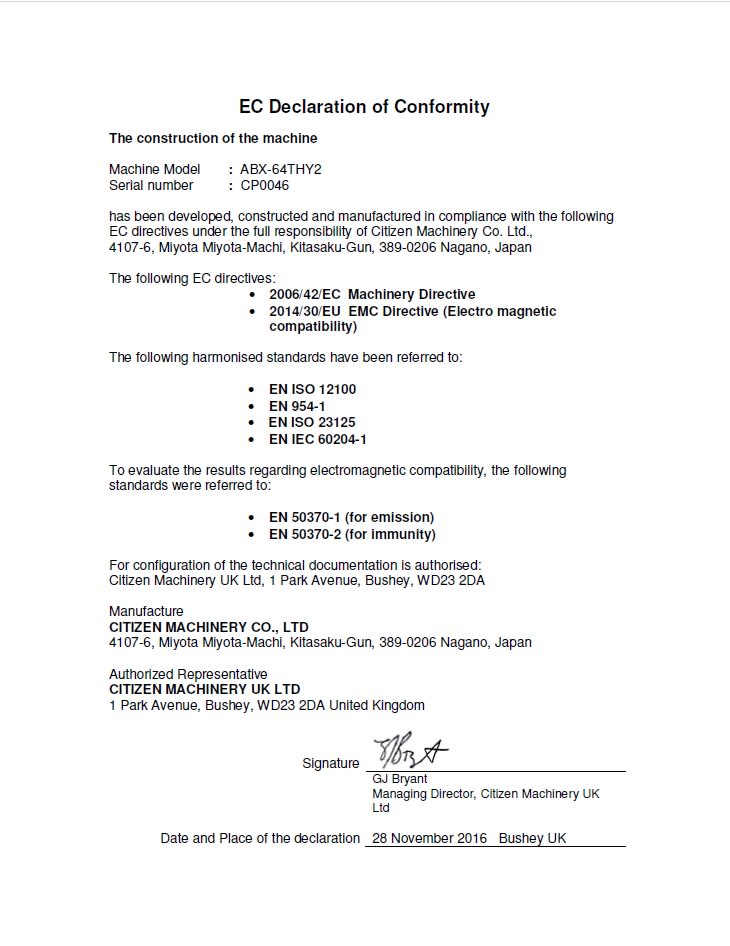

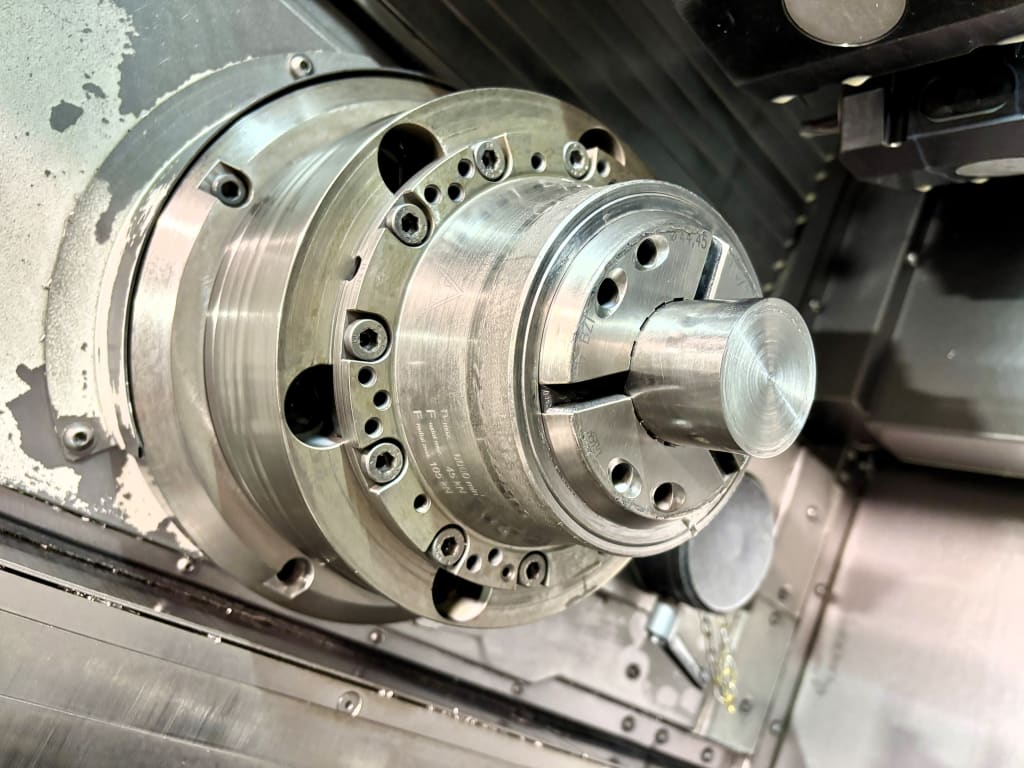

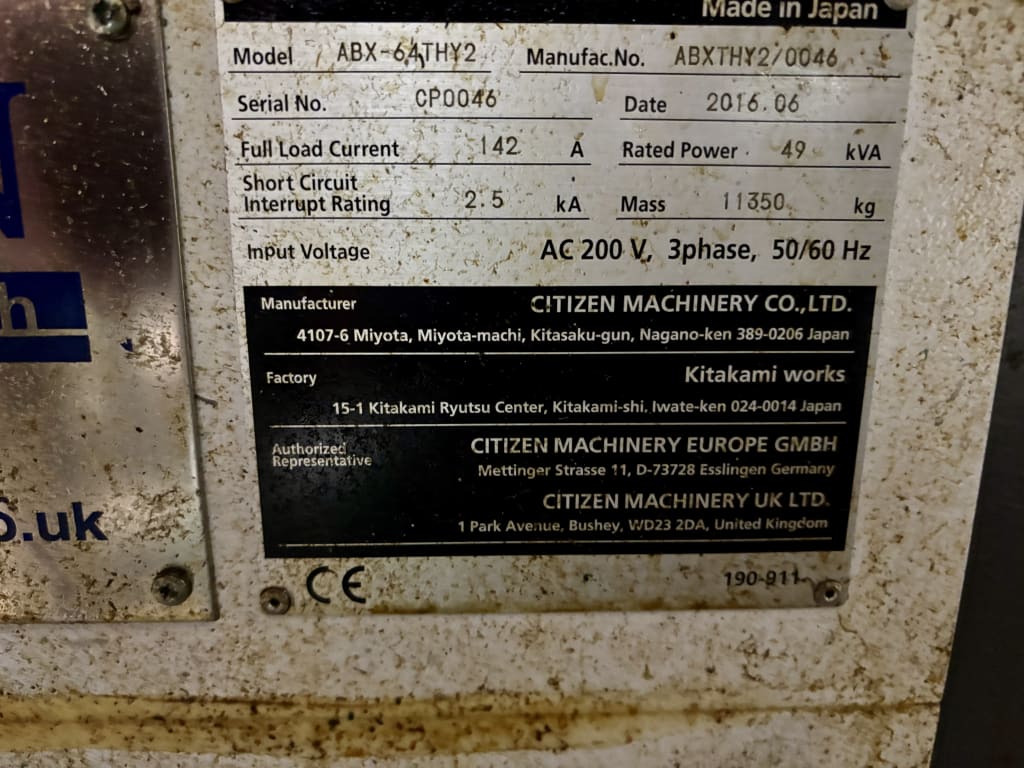

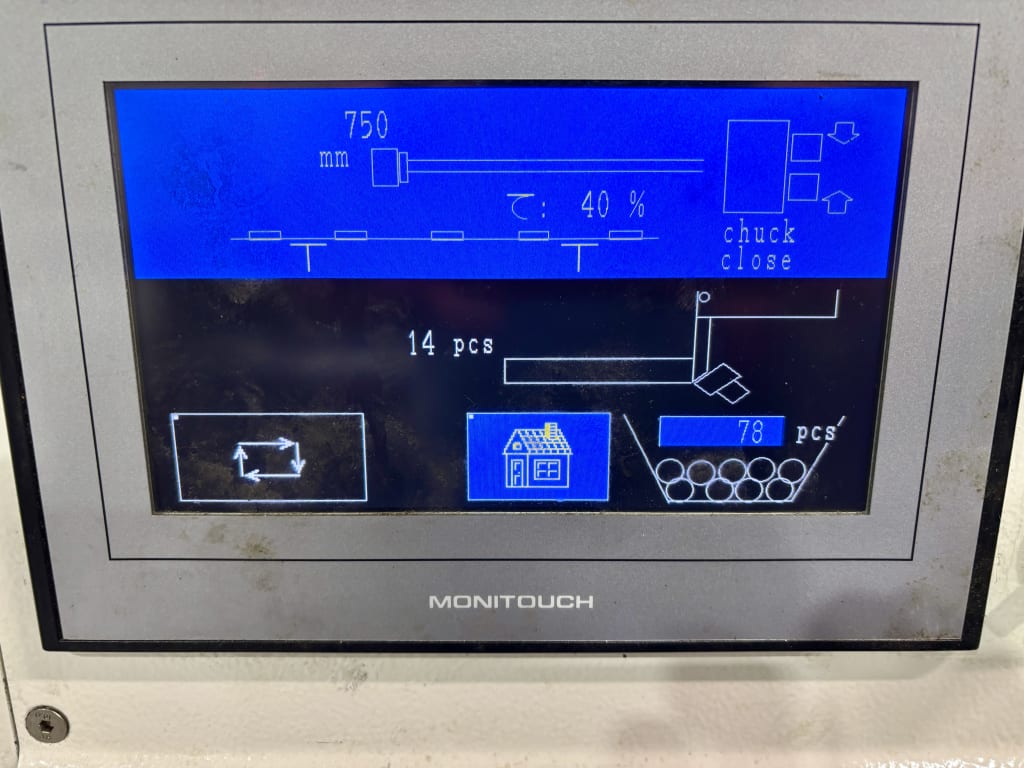

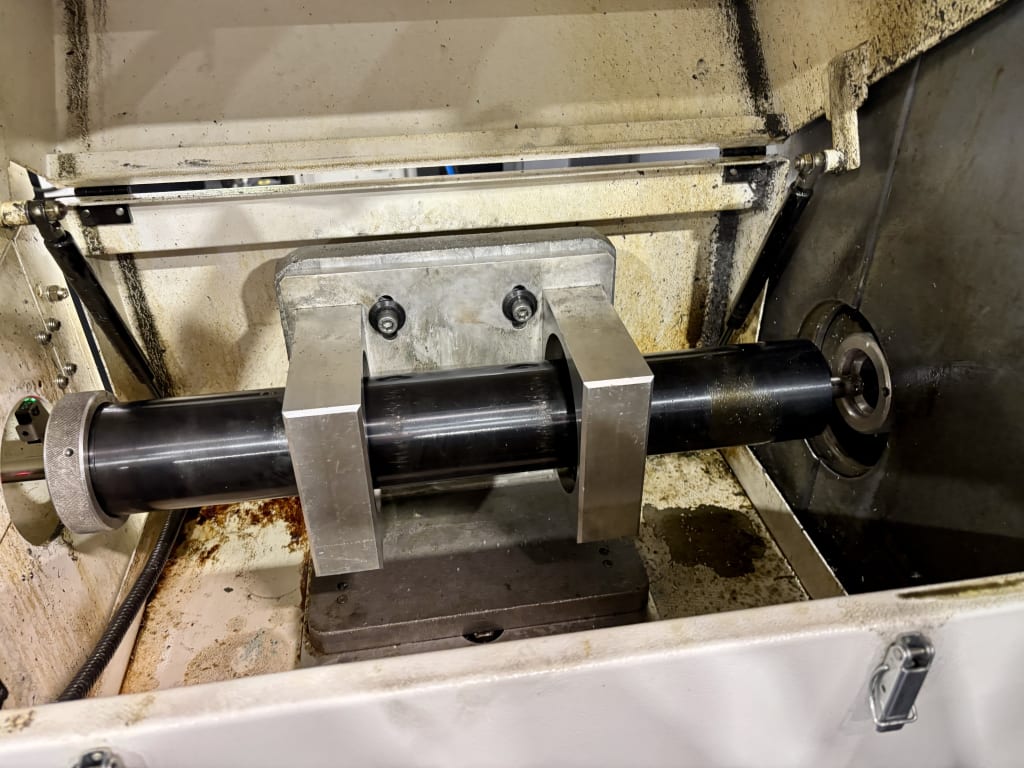

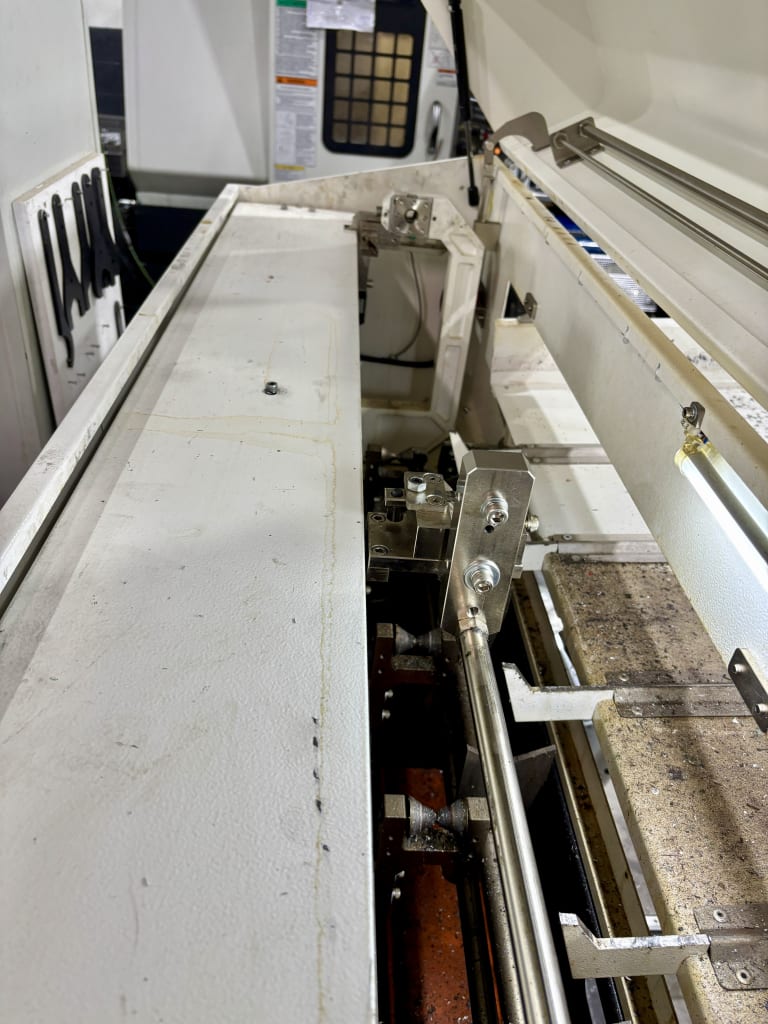

2016 Citizen Miyano ABX-64THY2 Twin Spindle, Triple Turret CNC Lathe With Fanuc Series 31i-B Control & Hydrafeed MSV80

Main Spindle Hainbuch Axfix 65 Collet Chuck. Sub Spindle Kitagawa B-206 Ø152mm 3 Jaw Power Chuck. Maximum Working Length S1=118mm, Sp2=125mm. Maximum Work Ø Bar Work SP1=Ø64mm, SP2=Ø51mm, Maximum Power Chuck Work SP1=Ø165mm, SP2=Ø165mm. Axis Travel Turret 1 'X'=190mm, 'Z'=270mm, 'Y'=±40mm, Turret 2 'X'=190mm, 'Z'=550mm, 'Y'=±40mm, Turret 3 'X'=190mm, 'Z'=270mm, 'Y'= ±40mm, SP2 'Z'=756mm. Spindle Speed Range SP1=40-4,000rpm (15kW Motor), SP2=50-5,000rpm (7.5kW Motor). Inner Ø Of Draw Tube SP1=Ø65.5, SP2=Ø52mm. 3- 12 Position Turrets, Turning Shank Dimension 20 x 20mm, Boring Bar Sleeve Ø25/40mm, Turret Index Time 0.25sec/Per Position. Rapid Traverse Turret 1 'X'=16m/min, 'Z'=30m/min, 'Y'=12m/min, Turret 2 'X'=16m/min, 'Z'=20m/min, 'Y'=12m/min, Turret 3 'X'=16m/min, 'Z'=20m/min, 'Y'=12m/min, SP1 'Z'=30m/min. Number Of Driven Tool Position 36 (12 x 3 Turrets), Driven Tooling Maximum Speed 6,000rpm (4.5kW Motor), Maximum Ø20mm Drilling, Maximum M14 x 2 Tapping, Maximum Ø20mm End Mill. Hydrafeed MSV80 Bar Feeder Length 2,180mm. S/No. CP0046 (2016). Hydrafeed S/No.S02-16H91. - LOT 3

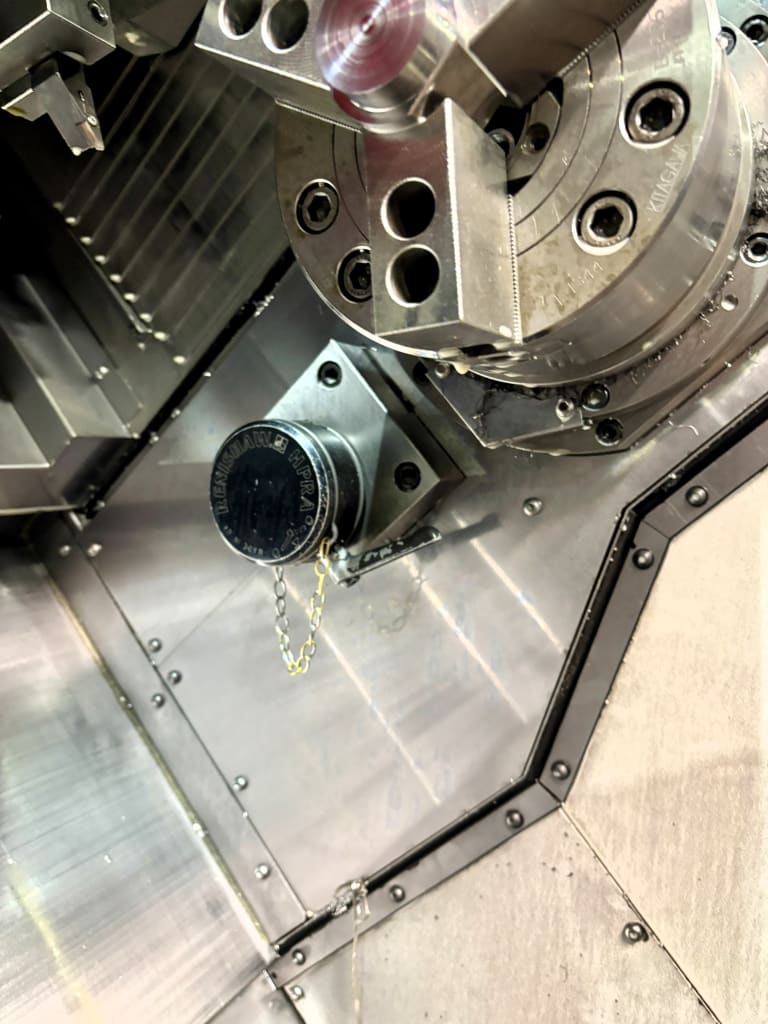

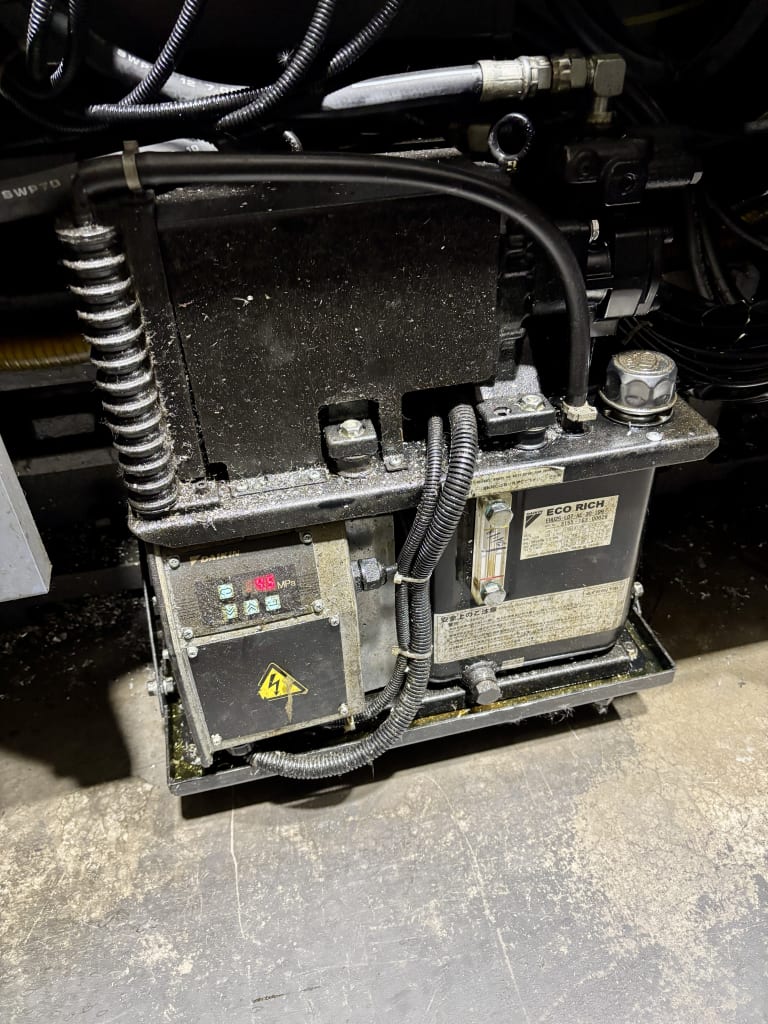

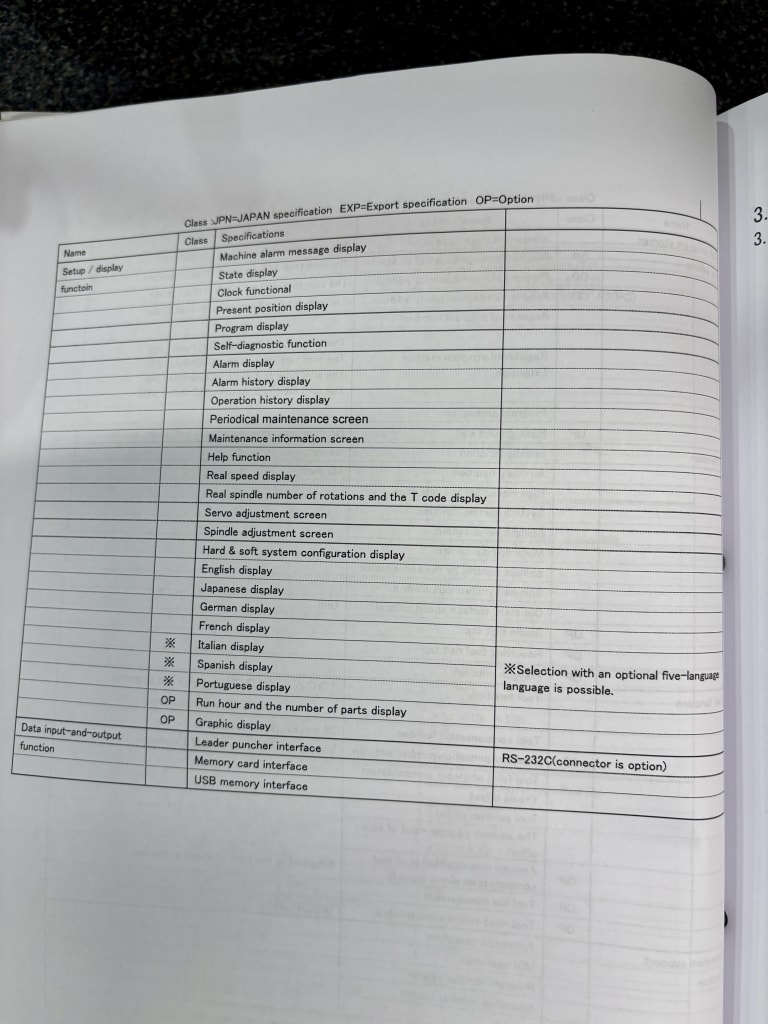

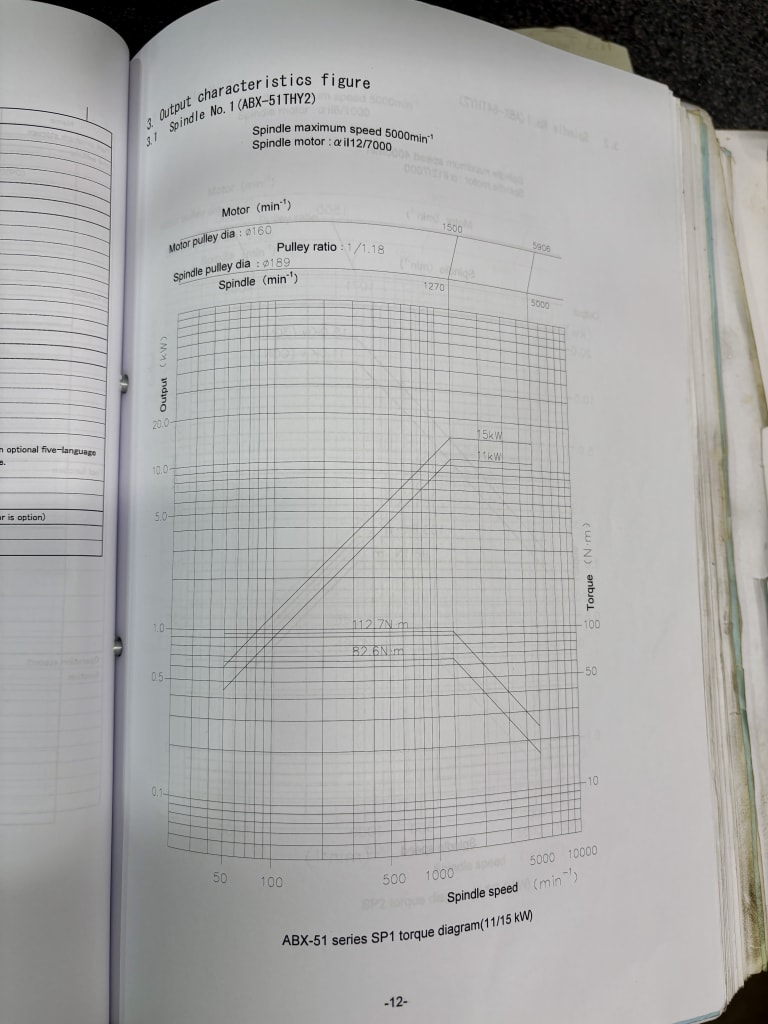

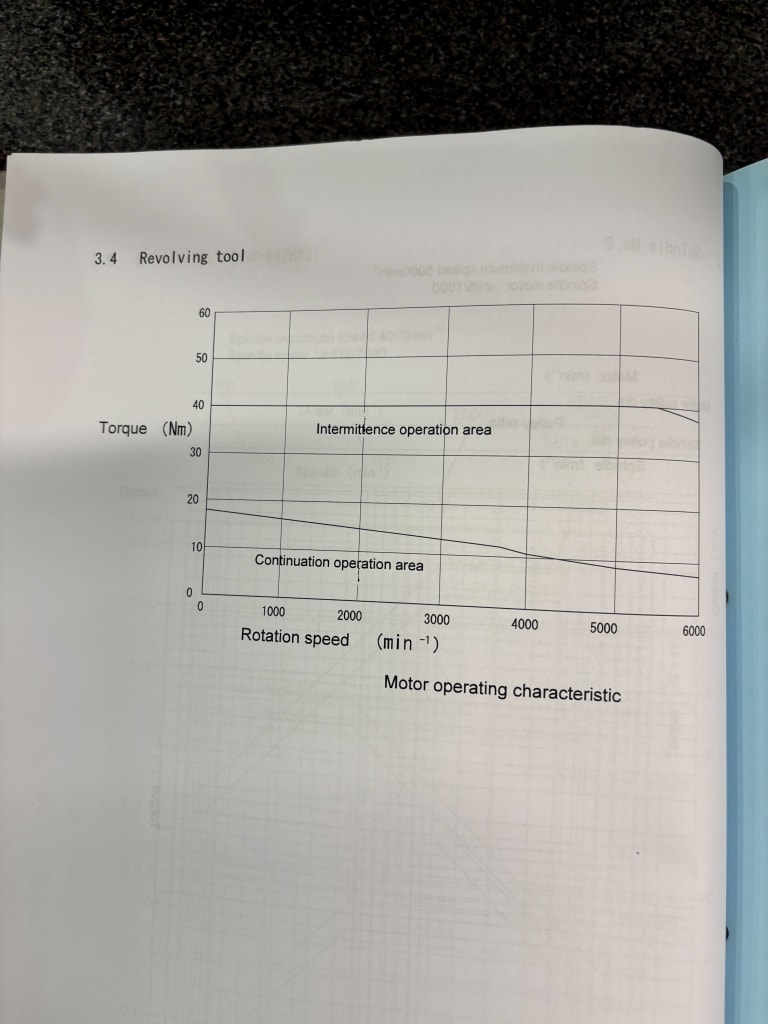

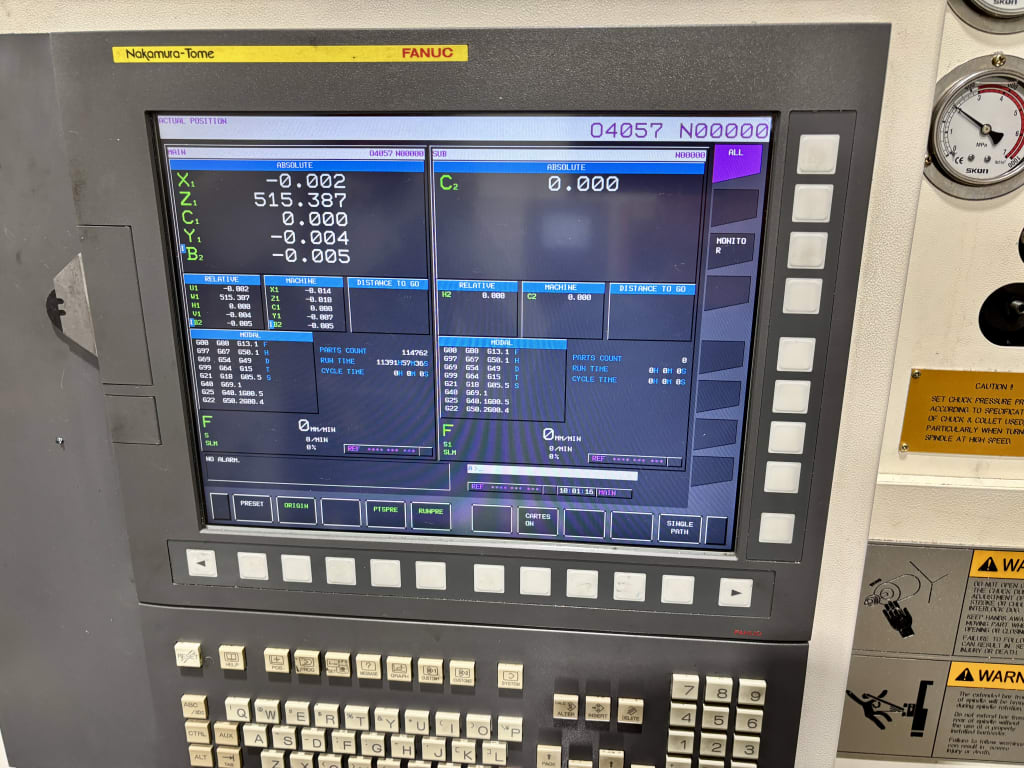

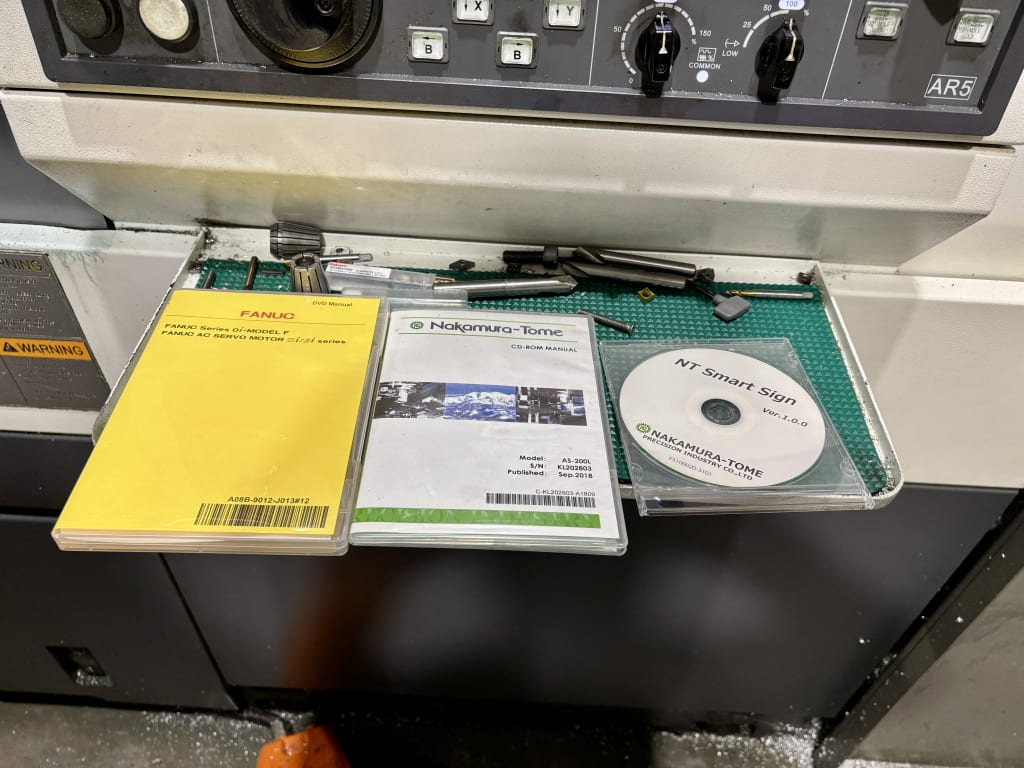

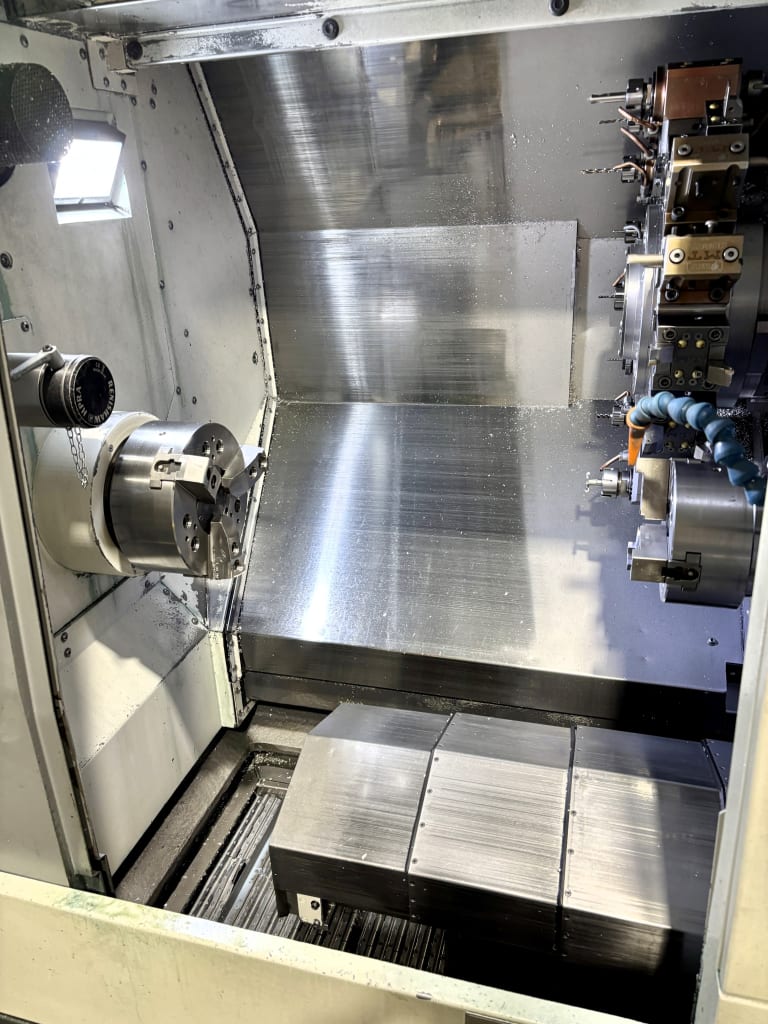

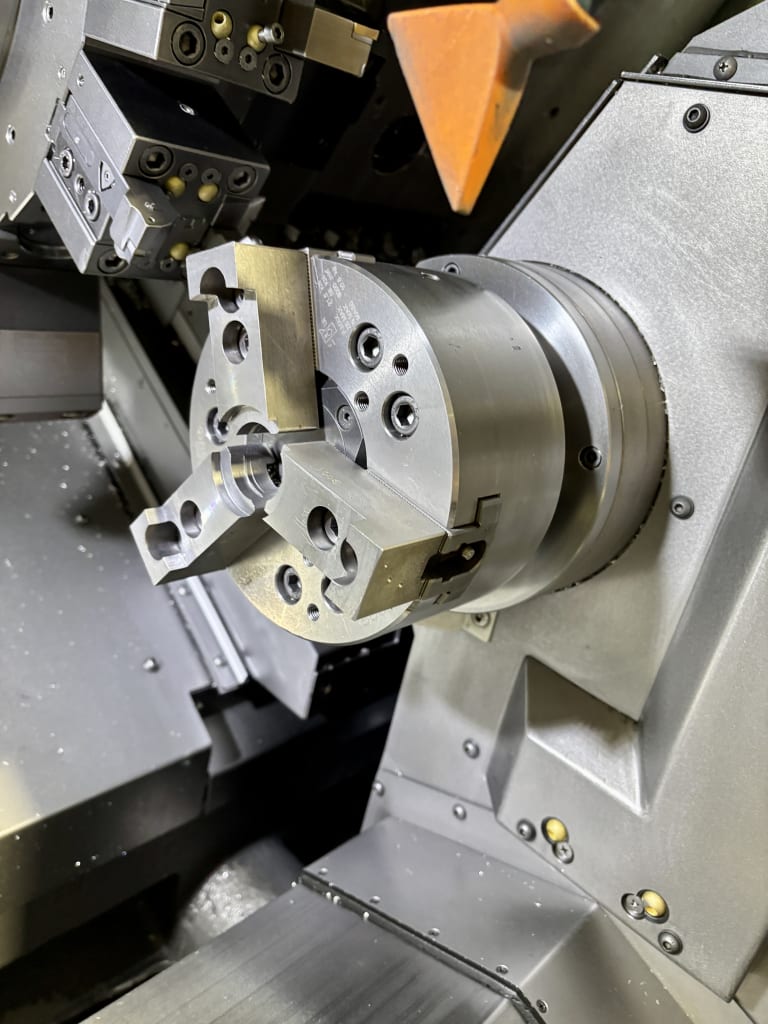

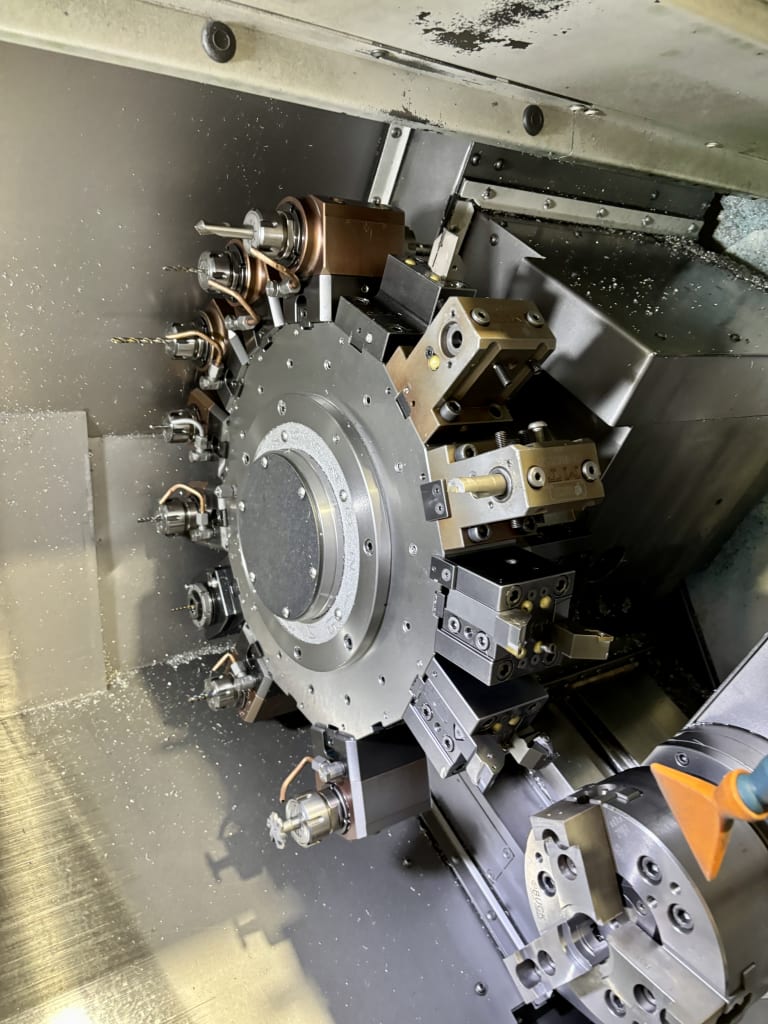

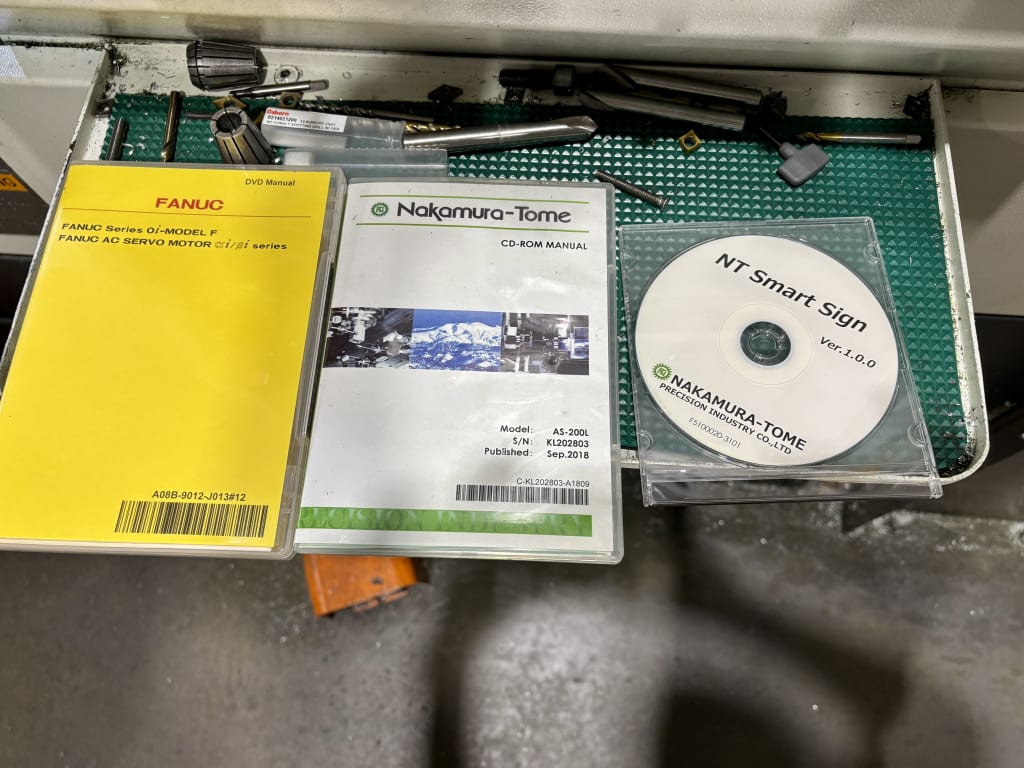

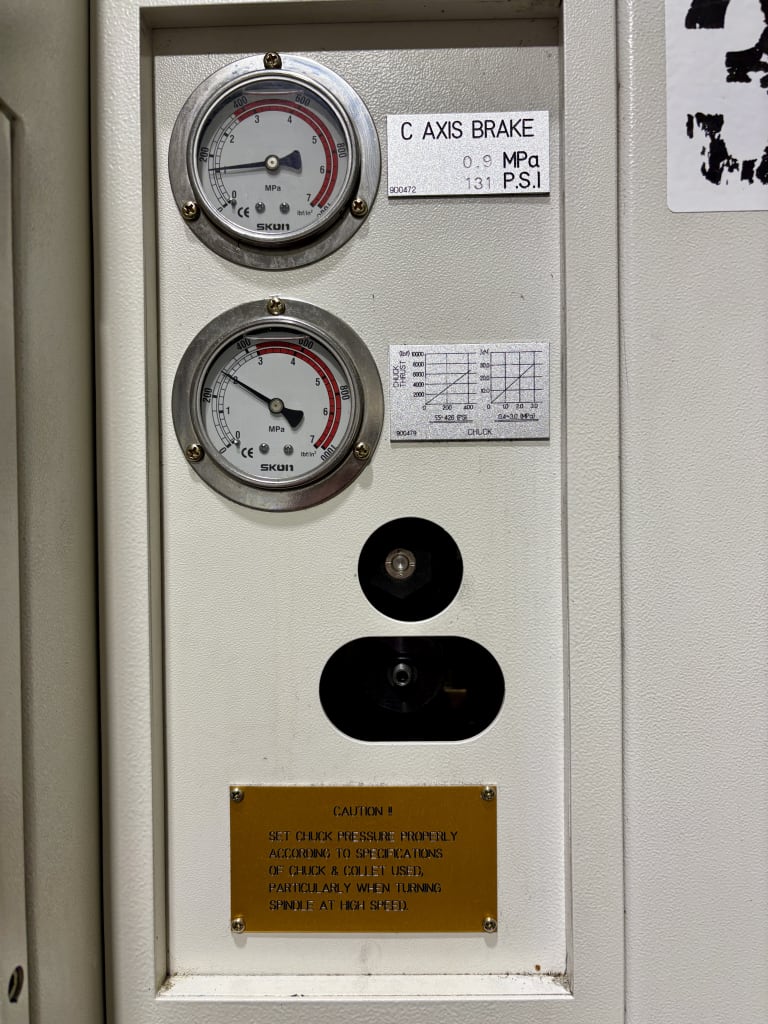

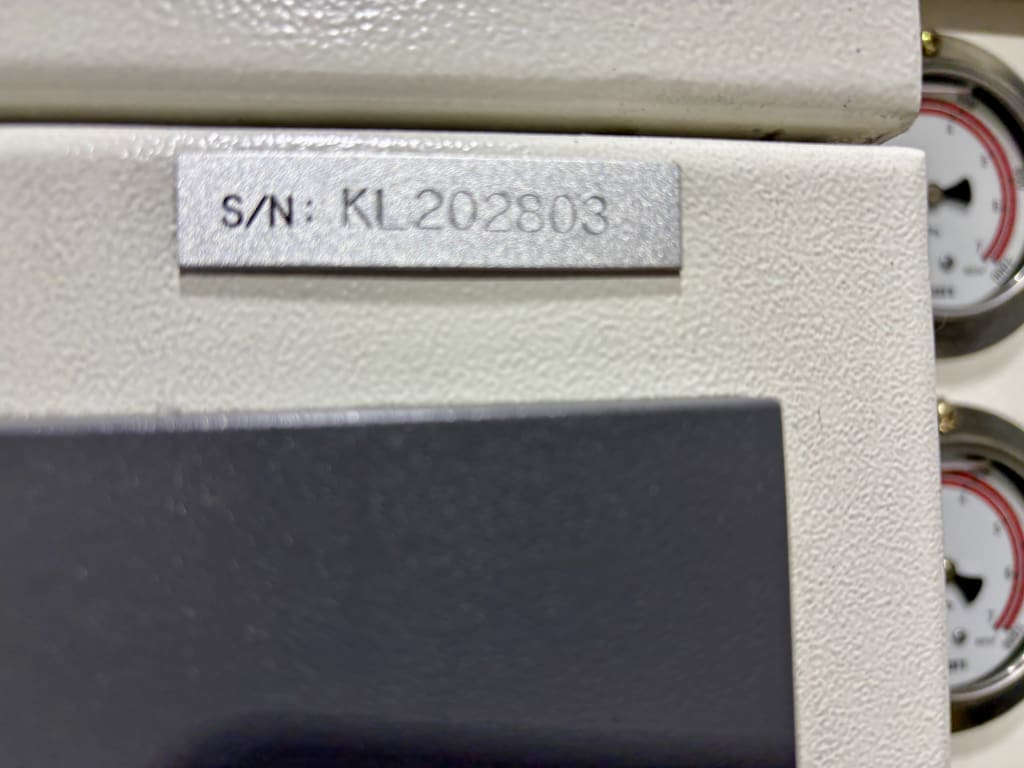

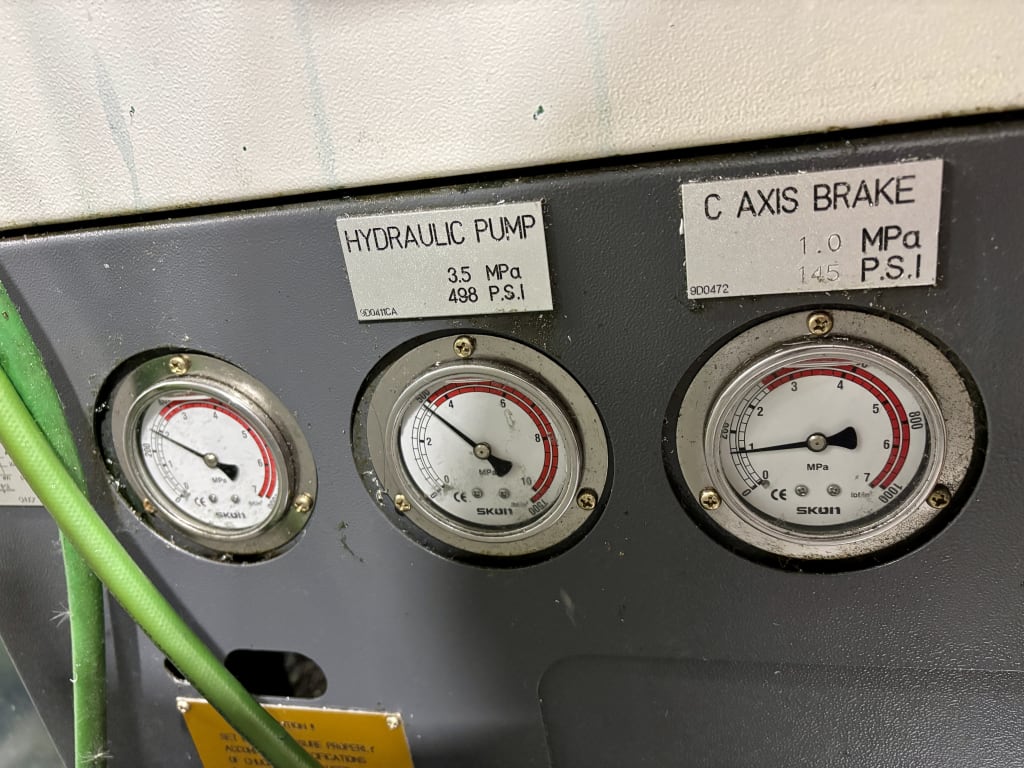

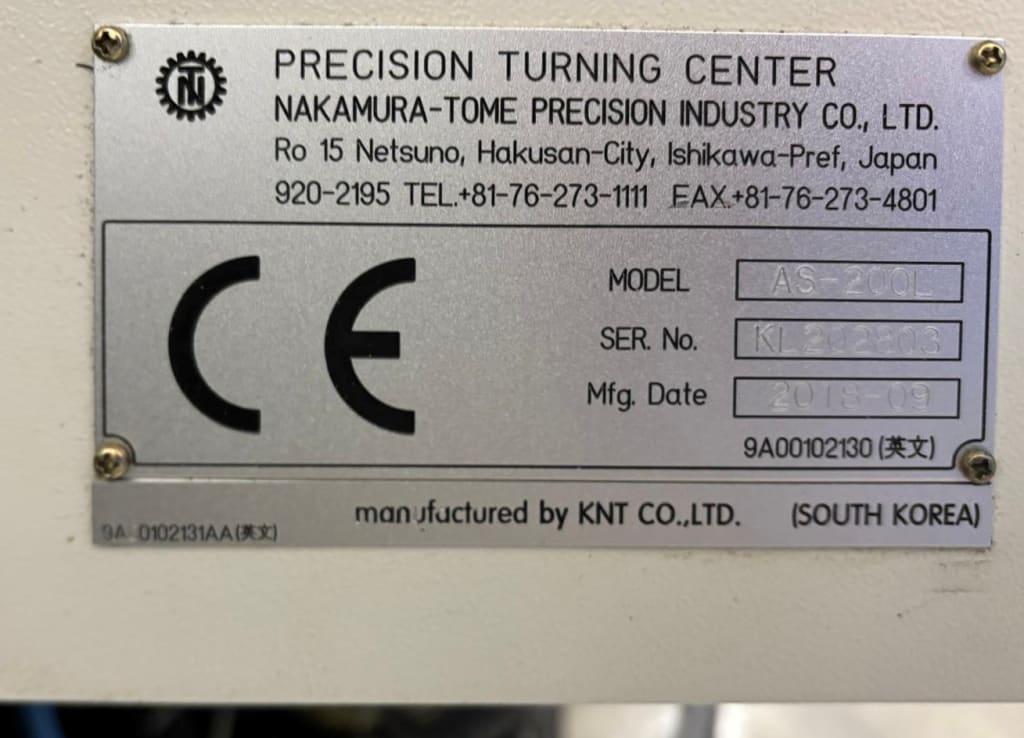

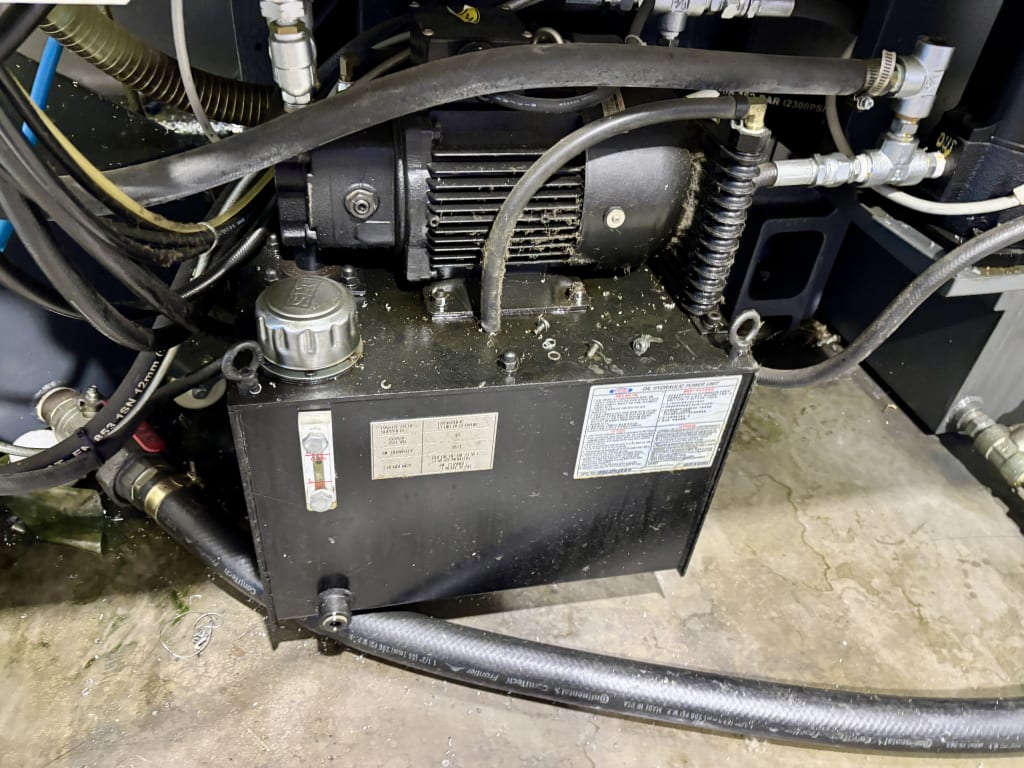

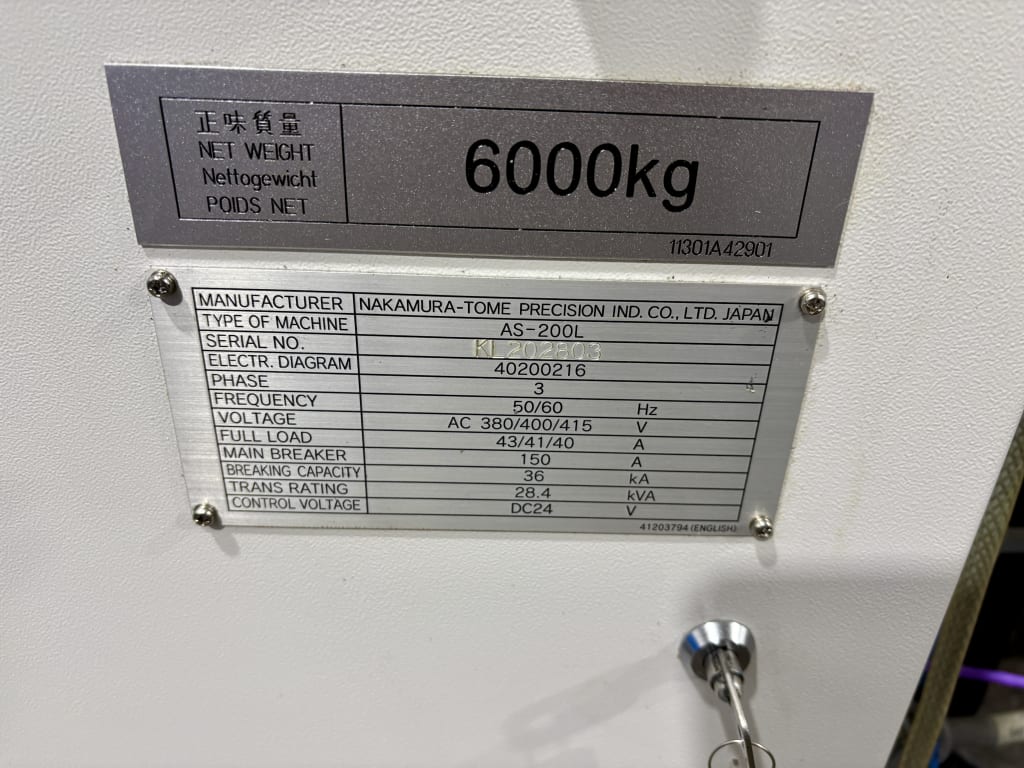

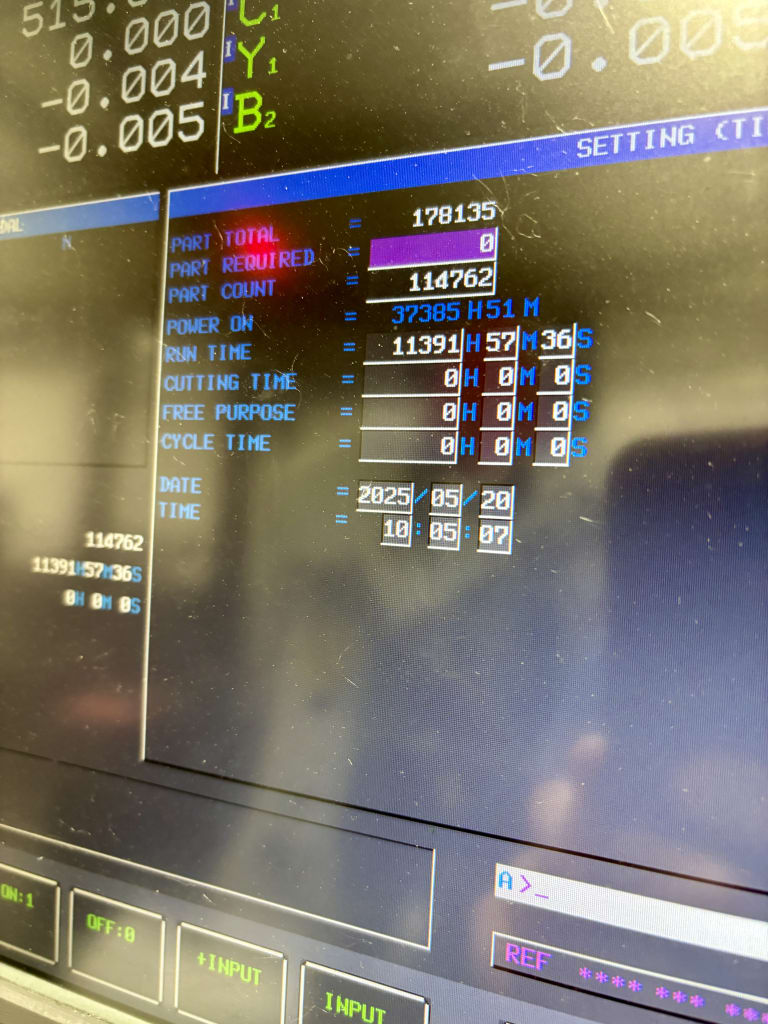

2018 Nakamura-Tome AS-200L Twin Spindle, Driven Tooling, 'Y' Axis CNC Slant Bed Lathe With Nakamura-Tome Fanuc Control

Buck BBC208 Ø215mm 3 Jaw Power Chuck, Sub Spindle Buck BBC206 Ø170mm 3 Jaw Power Chuck. Maximum Swing Over Bed Ø400mm. Maximum Turning Ø280mm. Standard Turning Ø190mm. Maximum Distance Between Spindles 800mm. Maximum Turning Length 570mm. Bar Capacity Ø65mm. Axis Travel 'X'=212.5mm, 'Z'=585mm, 'Y'=±41mm, 'C'=0.001°(Increment). Rapid Feedrates 'X'=24m/min, 'Z'=36m/min, 'Y'=6m/min, 'C'=600rpm. Maximum Main Spindle Speed 4,500rpm (Motor 15/11kW). Through Spindle Bore Ø80mm. Spindle Nose A2-6. Maximum Sub Spindle Speed 6,000rpm (Motor 7.5/5.5kW). Through Spindle Bore Ø56mm. Spindle Nose A2-5. Dodecagonal Drum Turret 15 Position. Tool Shank 25 x 25mm. Round Tool Bore Ø32mm. Driven Tooling Maximum Speed 6,000rpm (Motor 5.5/3.7kW), Number Of Milling Stations 15, Maximum Tool Ø1-16mm, Collet Dimension AR25. S/No. KL202803 (2018).

Essential Information

General Information

- Auction Dates

- Starts: 19 June 2025 at 12:00 BSTEnds: 31 July 2025 at 15:00 BST

- Site Address

- Apex Auctions CentreCatesby StreetKetteringNN16 8XNUnited Kingdom

- Viewing Days

- By Appointment OnlyViewings strictly by appointment only – Please contact Apex to make an appointment.

Fees & Payment

- Currency

- GBP

- Buyers Premium

- 18% or as specified on individual items

- Payment

General payment information

- Payment is due immediately on receipt of invoice.

- All payments must be made in the currency on the invoice issued.

- Accepted forms of payment are bank transfer ONLY. We do NOT accept payment by card, cash or cheque.

Goods

- Clearance days

- 11 August 2025 at 10:00 BST - 11 August 2025 at 16:00 BSTCollections strictly by appointment only. Must be collected on 11 August between 10am and 4pm.

- General Collection Information

Collection

Buyer will need versa lift to load to their transport.

- Buyers are fully responsible for removal of items plus all shipping and rigging charges.

- Items are only available to collect once the transfered funds have cleared, and a collection appointment has been booked.

- Buyers or third party movers must present an invoice to the on-site personnel when removing their items.

- Buyers must complete the removal of items within the clearance deadline. Normal removal hours are Monday to Friday, from 9am to 4pm (local time) unless otherwise stated.

- Contact and removal information will be emailed at the time invoices are issued.

- Sales Contacts

- Auction information